目录

返回顶部

How DigiKey Supports Robotics

Research and Development of Robots

The Structural Component

Fixed robots

Mobile robots

Control Systems and Software

Hardware

Software

Robot Operating System (ROS)

Actuators and Movement

Other Electrical Subsystems

Robotics

For more on Industrial robots

For more on educational robots

Robots use sensors to understand its surroundings, run logic, and perform actions. There's a large spectrum of robots though, it may be anything from a robot vacuum cleaner in a house, to a robotic arm that moves pallets in a distribution center.

Likewise, there's a wide range of people engaging with robots. There are folks building their own robots for competition, to folks that integrate robotic systems for factories.

Today, Industrial Robotics are utilized in everything from palletizing packages to welding, to pharmaceuticals and everything in between. The introduction of collaborative robots or cobots has created a working environment where humans and robots are able to work alongside one another to accomplish the workload. Robots have made their presence on the factory floor a necessity. In this magazine, we will cover safety around robotic cells, the application of sensor fusion in AMRs, the different robot configurations possible, and much more.

How DigiKey Supports Robotics

DigiKey is a proud supporter FIRST Robotics Competition, click to learn more. Pre-programmed machines that are focused on a single task. Small maker friendly robots like the XRP Robotics Platform, the STEVAL-ROBKIT1, or the Arduino based Tinkerkit Braccio allow students and hobbyists to explore the fundamentals of robotics without breaking the bank.

XRP Robot

SparkFun's XRP robotics platform includes everything users need to start their adventure into autonomous robotics.

STEVAL-ROBKIT1

The STMicroelectronics STEVAL-ROBKIT1 is a comprehensive robotics evaluation platform for the development of robotics technologies and applications. The modular design of the kit includes a main board, a motor control board, and an imaging board.

TinkerKit Braccio

The TinkerKit Braccio is a fully operational robotic arm, controlled via Arduino. It can be assembled in several ways for multiple tasks such as moving objects.

DigiKey also provides functional robots that get used in factory settings, like the Kuka robot kit or the Igus Rebel. These machines are customized with programming and typically have numerous safety interlock systems both for the machine and user safety. For information on Automation & Control robots at DigiKey, click here.

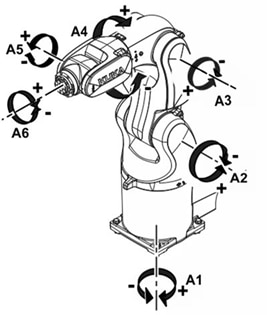

Image from Kuka's robot kit

Image from Kuka's robot kit

Research and Development of Robots

DigiKey has a longstanding history of providing components, and robots are no exception. The remainder of this page will focus on those looking to do their own research and development of robots, for others please use the links above to find the robots most suited for your use case.

Image from NXP's NavQPlus

Image from NXP's NavQPlus

The Structural Component

The structural component of a robotic system is what turns it from a collection wires, cables, and motors into something that can move and interact with the surrounding environment.

Typically referred to as Chassis, case, or enclosure the structural component of a robot is the components that act as the container for the robot's subsystems. It could include arms and the motors for fixed robots and wheels along with the drive systems for mobile robots.

Fixed robots

Fixed robotic platforms are commonly found in manufacturing and assembly lines where the reliability, precision placement and positioning and repeatability of actions are required.

There are many different types of fixed robotic platforms typically divided up by how the robot moves or what application the robot is designed for:

Articulated robot – has a series of motors and rotary joints that move within several degrees of freedom which is useful for industrial robot arms to perform welding, painting, or moving parts

Articulated robot – has a series of motors and rotary joints that move within several degrees of freedom which is useful for industrial robot arms to perform welding, painting, or moving parts

SCARA robot – Selective Compliance Assembly Robot Arm (SCARA) can move across the X and Y axis planes of movement but are limited in the vertical or the Z axis. This makes SCARA robots popular for applications on a flat surface such as pick and place operations

SCARA robot – Selective Compliance Assembly Robot Arm (SCARA) can move across the X and Y axis planes of movement but are limited in the vertical or the Z axis. This makes SCARA robots popular for applications on a flat surface such as pick and place operations

Delta robot – is designed for high-speed maneuvering of light weight objects. They are used for pick and place operations, though a delta robot has 3 arms that look a little like spider legs, which sometimes gets this robot called a 'spider' robot

Delta robot – is designed for high-speed maneuvering of light weight objects. They are used for pick and place operations, though a delta robot has 3 arms that look a little like spider legs, which sometimes gets this robot called a 'spider' robot

Cartesian / gantry robot – also called a linear Robot, is a type of industrial robot where all three axis of movement are linear, traveling in straight line rather than rotating around a pivot point like a motor

Cartesian / gantry robot – also called a linear Robot, is a type of industrial robot where all three axis of movement are linear, traveling in straight line rather than rotating around a pivot point like a motor

Cobot – short for collaborative robot is a new type of robotic arm platform where interaction and collaborative work with other humans is not only expected but planned for, designed to be safe to work around humans. Cobots have force feedback sensors to detect collisions with humans

Cobot – short for collaborative robot is a new type of robotic arm platform where interaction and collaborative work with other humans is not only expected but planned for, designed to be safe to work around humans. Cobots have force feedback sensors to detect collisions with humans

Fixed robots have parts including:

Robotic Arm – the motors, frame, cabling and structural elements to make the moving parts of the robotic device

Robotic Arm – the motors, frame, cabling and structural elements to make the moving parts of the robotic device

End Effector – the device or mechanism that contacts the object being moved by the robotic arm, these can be a mechanical grabber, a pneumatic suction cup, or a tool (such as paint sprayer or probe)

End Effector – the device or mechanism that contacts the object being moved by the robotic arm, these can be a mechanical grabber, a pneumatic suction cup, or a tool (such as paint sprayer or probe)

Mobile robots

As the name suggest Mobile robots are robots that are not fixed to one location but are able to move in a space, either along a fixed track or freely in the environment. The use of internal batteries and electric motors to self-propel the mobile robot give them a separate set of challenges to overcome.

Here are some groups within mobile robots:

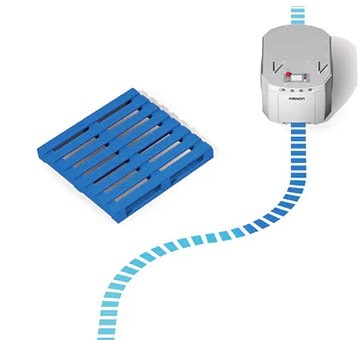

Automated Guided Vehicle (AGV) – is a type of mobile robot that follows a predefined path, typically an embedded wire track, magnetic tape, or optical navigation. Commonly found in controlled environments such as moving material inside warehouses or other finished spaces.

Automated Guided Vehicle (AGV) – is a type of mobile robot that follows a predefined path, typically an embedded wire track, magnetic tape, or optical navigation. Commonly found in controlled environments such as moving material inside warehouses or other finished spaces.

Autonomous Mobile Robot (AMR) – is a type of robot that can move through its environment independently, without any predefined path or user interaction. An AMR has enough sensors and processing power on board that it can identify and maneuver around obstacles and changes in the environment. While this does make a more flexible robot, the complexity and cost increases.

Autonomous Mobile Robot (AMR) – is a type of robot that can move through its environment independently, without any predefined path or user interaction. An AMR has enough sensors and processing power on board that it can identify and maneuver around obstacles and changes in the environment. While this does make a more flexible robot, the complexity and cost increases.

Let’s Talk Technical on Robotics and Physical AI

In this video, Shawn Luke (DigiKey), Bob Card, and Theo Kersjes (onsemi) explore the intersection of Robotics and Physical AI, with a focus on how autonomous mobile robots (AMRs) are transforming industrial and commercial environments.

Autonomous Mobile Robot Types and Applications

This article compares and contrasts traditional mobility solutions such as conveyor systems and automated guided vehicles (AGVs) with AMRs. It looks at the benefits of using AMRs and how the proliferation of AMR designs is expanding their utility

Control Systems and Software

For a robot to perform tasks and do useful work it must evaluate inputs from sensors and issue outputs to actuators. The control system sits between those inputs from the sensors and the outputs to the actuators. The control system contains the logic and algorithms that decide how the robot will function.

Hardware

Processing hardware is the physical embedded system (or the brains of the robotic system) that enables processing of instructions and storage of data.

There are many different types of processing hardware available for robots depending on both the complexity of the decisions to be made and the type of robotic platform. Here are a couple of common ones:

Programmable Logic Controllers (PLCs) are modular industrial computers ideal for fixed industrial robots as they can process data collected in real time. The typical larger size and networking options means one stationary unit can control multiple robots.

Programmable Logic Controllers (PLCs) are modular industrial computers ideal for fixed industrial robots as they can process data collected in real time. The typical larger size and networking options means one stationary unit can control multiple robots.

Microprocessors (MPUs) or other embedded platforms such as Single board computers (SBC) can be used when robots need to be mobile but still retain enough processing power to evaluate complex data such as machine vision cameras or autonomous driving.

Microprocessors (MPUs) or other embedded platforms such as Single board computers (SBC) can be used when robots need to be mobile but still retain enough processing power to evaluate complex data such as machine vision cameras or autonomous driving.

For more information about the different types of processing hardware be sure to check out the Application and Technology page about Embedded technologies which can be found here.

Software

The robotic software is the set of operating instructions for the robotic platform, telling it where to move, what to grab or when to perform these actions. Typically, this program is executed on a Microprocessor and is written in the programming language C/C++ or Python as both programming languages have long histories of well-developed robotic programming libraries.

However, as Cobots and other machines designed for working with humans in proximity become more common, graphical programming and user interfaces are becoming more and more common.

Robot Operating System (ROS)

The robot operating system (ROS) is a powerful and flexible software framework that was developed for robotic development. ROS is not a true operating system; it is in fact more accurately called a middleware application that needs an operating system like Windows or Linux to work with. First released in 2007 ROS has grown into a large community of developers around the world working on everything from educational and hobby robotics to industrial platforms.

ROS is filled with software tools and prewritten libraries that help robotic developers. Like other software frameworks, ROS provides hardware abstraction and low-level device control, for example to create drivers to interface components to the operating system. A Real Time Operating System (RTOS) spin off project ‘Micro-ROS' is available for robotic platforms that run off a microcontroller systems.

As ROS allows for a framework of the sensors and motors that make up a robot, ROS can allow you to work with a simulated version of the robot (it's "Digital Twin".)

Intro to ROS Part 1: What is the Robot Operating System (ROS)?

The Robot Operating System (ROS) is an open-source framework designed to simplify the development of robotic systems. In this post, we’ll introduce ROS. We’ll focus specifically on ROS 2, which is the current and actively developed version of the framework.

Adding Object Detection Vision to the XRP Robot

The XRP includes several activities to navigate a course, identify and avoid collisions with walls, follow lines. However, I wanted to take the robot to the next level, specifically, I added a low-power camera running a custom-trained object detection model to identify and manipulate objects.

How SMEs Can Use an Industrial Metaverse to Explore and Deploy Robotic Solutions Rapidly

Robots and collaborative robots (cobots) are on the leading edge of factory automation technologies. Digital twins and virtual reality (VR) are on the leading edge of design and development tools. Combined, they can be leveraged to create an industrial metaverse that delivers higher productivity faster.

Actuators and Movement

Actuators and motors are the devices that allow robotic platforms the ability to move across the working space and provide force to manipulate objects. This may mean a motor powering a mobile robot to move itself across a factory floor, or a robotic arm picking up an object to stack on a pallet.

Actuators can be driven by multiple forces including fluid (hydraulics), or air (pneumatics). Each of these power systems have their own advantages and drawbacks. For this page we will be looking at electrical power since it is the most common for robotic systems.

Source DigiKey Part Number 1738-1385-ND

Source DigiKey Part Number 1738-1385-ND

Servo motors typically contain both a Position encoder and controller to control position and speed. This allows for a computerized controller to accurate know the position, orientation and speed of a servo motor shaft, making it useful for movement and sensing applications.

Source DigiKey Part Number 1471-1491-ND

Source DigiKey Part Number 1471-1491-ND

Stepper motors are electric motors that, instead of spinning freely, rotate a fixed number of degrees, used for high precision positioning applications where repeatability and accuracy are needed. Stepper motors are also often chosen because of the higher hold power and higher torque they have over other DC motors.

Source DigiKey Part Number PEC12R-4220F-N0024-ND

Source DigiKey Part Number PEC12R-4220F-N0024-ND

Encoders are a device that can provide position, or speed of a rotating shaft. Encoders can be classified in many different types depending on the output type and sensing method that the device is using.

- Incremental Encoders can show which direction and how fast the fast is rotating by the output signals

- Absolute Encoders maintain position information set at the time of manufacture and doesn't require later calibration

Motor Drivers are modules that amplify low power signals from an embedded system to larger signals that can control a motor. Motor drivers specialize in the precise control of a motor's speed and direction.

End Effectors / End of Arm Tooling (EOAT)

Source DigiKey Part Number 4358-MG400Vacuum Suction Cup kit-ND

Source DigiKey Part Number 4358-MG400Vacuum Suction Cup kit-ND

End effectors are the devices and tooling at the end of the robotic arm that physically grabs onto the object being manipulated. They can be found in as a physical claw that holds an object or a suction cup that vacuums onto a surface. More advanced end effectors can have sensors and multitool capabilities built in.

How to Use Servo Motors with the Arduino UNO

In this How-To article, we will learn what servo motors are, where you may use them, and how to use them!

The Basics of Stepper Motors

There are several types of electric motors, each with their own advantages and disadvantages. You may consider servo motors, which typically only have 180° of rotation. Today we’ll evaluate the pros and cons of the hybrid stepper motor and see how it works.

Other Electrical Subsystems

Robotics solutions often also contain anything from power, sensors, and cabling. Also, check here for more industrial automation components.

Power – Providing power to the robotic platform needs to be both small and compact enough to either fit within or near by the robot to but also provide enough stable electrical power to ensure proper operations. The combination of power and efficiency is a primary objective for power designers working on robotics.

Power – Providing power to the robotic platform needs to be both small and compact enough to either fit within or near by the robot to but also provide enough stable electrical power to ensure proper operations. The combination of power and efficiency is a primary objective for power designers working on robotics.

Wire and Cable – Robotic platforms have more extreme operating considerations than other applications. Wire and cable in robotics often needs to flex and bend along with the robot. The different networking protocols such as Ethernet, Modbus or IO-Link all would require different connectors to ensure proper connections and Physical accessories such as drag chains provide tension relief.

Wire and Cable – Robotic platforms have more extreme operating considerations than other applications. Wire and cable in robotics often needs to flex and bend along with the robot. The different networking protocols such as Ethernet, Modbus or IO-Link all would require different connectors to ensure proper connections and Physical accessories such as drag chains provide tension relief.

Sensors – Acting as the robots' eyes and ears allowing the robot to take in data from the environment around it. By leveraging cameras, distance sensors, and pressure sensors, robots are able detect recognize and apply the level of force needed perform the desired task.

Sensors – Acting as the robots' eyes and ears allowing the robot to take in data from the environment around it. By leveraging cameras, distance sensors, and pressure sensors, robots are able detect recognize and apply the level of force needed perform the desired task.

Machine safety – Devices that help identify if any people or other objects could be at risk from a robot, these devices include light curtains (which are optical sensors like the safety mechanism on a garage door).

Machine safety – Devices that help identify if any people or other objects could be at risk from a robot, these devices include light curtains (which are optical sensors like the safety mechanism on a garage door).

Building Humanoid Robots: From Concept to Connector

Humanoid robots represent one of the most demanding applications in engineering—where every signal, movement, and data stream must perform flawlessly in motion. Join us as we share with you information on design priorities, common pitfalls, and connector solutions enabling the latest advancements in humanoid robotics.

Safety in manufacturing

Manufacturing has the potential to be one of the most dangerous places on Earth. Without proper mitigation through safeguards workers in this environment face serious bodily harm or worse. The technologies featured in this collection are just a small selection of safety solutions available at Digikey.