目录

返回顶部

Emerging Trends

48 Volt Electrical System

Zonal Electric/Electronic (E/E) Architecture

Software Defined Vehicle (SDV)

EV Chargers

Charger Categories

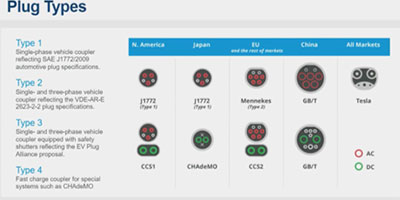

Plug Types

Wide Bandgap Semiconductors for Transportation

Advantages of SiC power devices

Advantages of GaN power devices

How WBGs are impacting transportation systems

Systems within EVs reaping the benefits of WBG Semiconductors

In-vehicle networks (IVNs) and CAN Bus

CAN Bus

Variations on CAN bus that support higher data rate applications

Other protocols used in In-vehicle networks (IVNs)

The hybrid reality of modern In-vehicle networks (IVNs)

Sensors for Transportation

Distance and position sensors

Other sensors

Automotive Subsystems

Automotive Qualification and Grade

AEC standards

Reference Designs

Brushed DC (BDC) motors

H-bridge motor driver

Transportation and Automotive

Transportation like planes, trains, and automobiles have traditionally had low voltage systems for accessories. Those continue today and are expanding in the electrification of transportation to high voltage systems that run the primary motors.

Emerging Trends

There is a new wave of technologies for the transportation market that promise a smarter and more efficient experience, here are just a few that DigiKey suppliers are currently working on.

48 Volt Electrical System

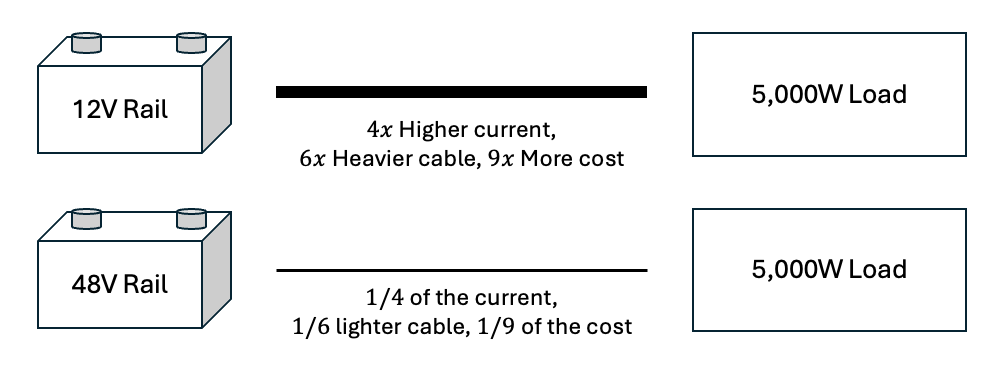

The higher operating voltage of the 48V system allows for smaller and lighter wires

The higher operating voltage of the 48V system allows for smaller and lighter wires

Most automobiles of the last 70 years have used the 12 volt (12V) electrical distribution system on board the car, powering everything from the electric starter to the radio to the power windows. However, as more systems (like driver safety and infotainment) are added to a car, the electrical requirements are growing beyond what the standard 12V system can efficiently provide.

The introduction of the 48 volt (48V) electrical system on modern automotive platforms allows for improvement in not only current carrying but also improvements in overall efficiency. The move to 48V electrical systems offers numerous advantages over the traditional 12V systems here are just a few benefits of the switchover.

- Same Power with Lower Current - By increasing voltage, the same amount of electrical power can be delivered with a smaller amount of current. (For example, a 1 kW electrical load powered by 12V needs 83 amps to be delivered. At 48V the same electrical load current requirements drop to just under 21 amps.)

- Improved Efficiency – Reducing the wire gauge, makes the wiring harness smaller and lighter making the overall car lighter weight. The reduction of current also improves the electrical efficiency of the power distribution system by reducing power loss in the wires and connectors.

- Safety Advantages - 48V is higher risk generally then 12V, however it is still considered a safe voltage to work with in dry conditions, and while maintaining safety standards. The safety benefits come from the lower current and lower heat generation, these result in lower likelihood of overheating and electrical fires.

- Supports Hybridization and Electrification - The 48V electrical system was key in the adaption of the mild hybrid transportation technology. The 48V system can power electric motors and systems assisting the traditional internal combustion engine.

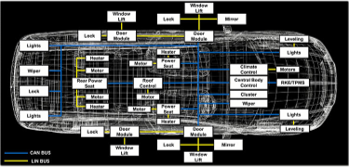

Zonal Electric/Electronic (E/E) Architecture

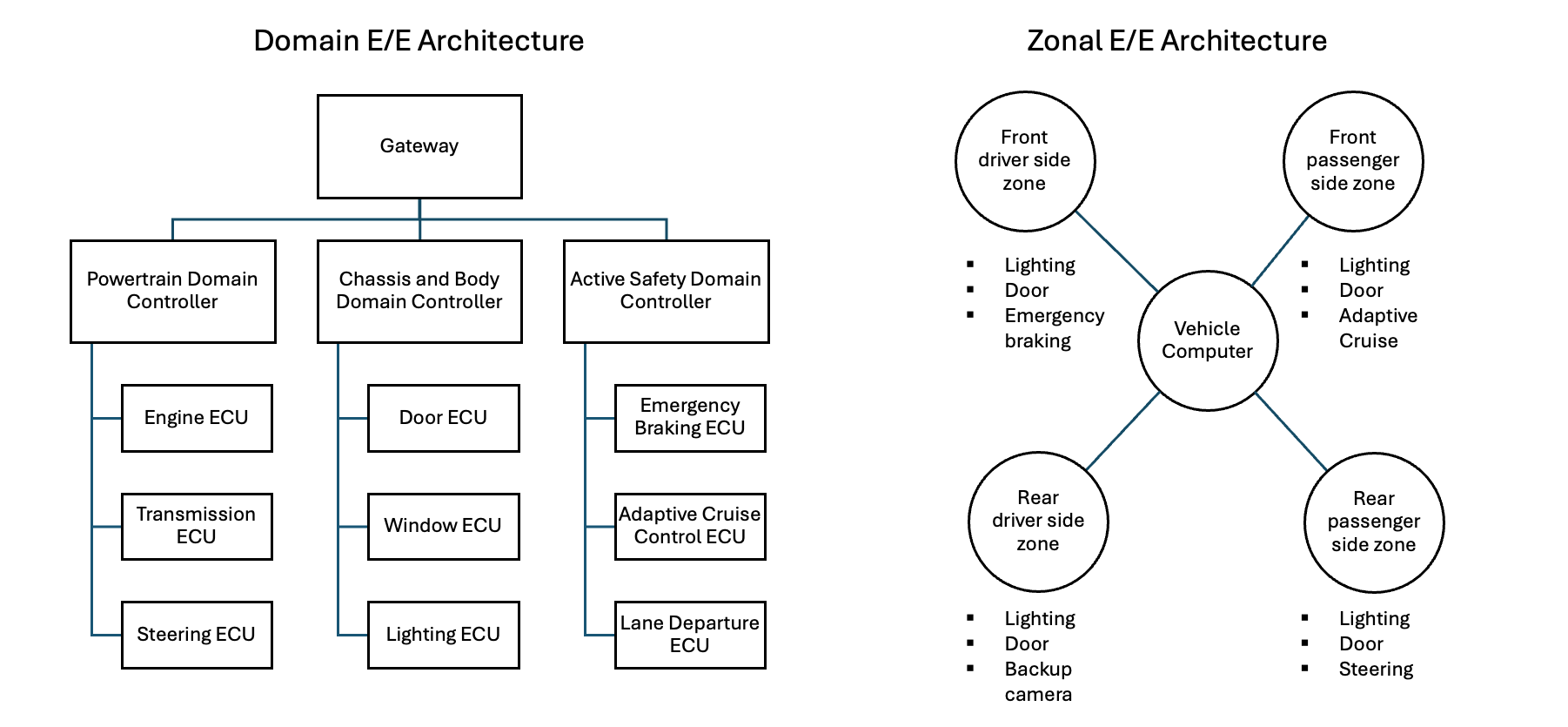

Zonal architecture in vehicles organizes electronic systems based on physical location (zones) rather than function, using zone controllers to manage local devices within each zone

Zonal architecture in vehicles organizes electronic systems based on physical location (zones) rather than function, using zone controllers to manage local devices within each zone

As electronic control units (ECUs) were added to automobile systems, these units were typically single tasked, focused on a particular subsystem. For example, engine control, transmission state, and breaking control. The ECUs needed to be rugged, durable, and have a long-life span.

As more ECUs were added, they were typically grouped and network together by functionally or domain, powertrain ECUs linked together to communicate engine status, passenger cabin ECUs networked together for passenger control. However, the resulting mass of differing and overlapping networking connections added more weight and wiring complexity to an already over crowed vehicle. With the increasing demand for both electrical system complexity and reduced vehicle mass, a new system architecture was needed .

Zonal architecture was developed for modern automotive systems both to reduce weight and complexity of the wiring harness and to improve responsiveness of the electrical subsystems and sensor inputs. Instead of multiple independent ECUs scattered across the vehicle frame networked to a central domain controller, zonal architecture has multiple subsystems in close physical proximity networked together to a zone controller able to coordinate between zones and a central computer.

Whereas domain architecture had dedicated controllers for controlling lights, which resided in one location on the vehicle and then ran all wiring through a dedicated fuse box (solving the problem with lots of wiring). Zonal architecture decentralizes a function like lighting, allowing multiple zone controllers to take on that task. Likewise, eFuses decentralize the dedicated fuse box, and in turn significantly reduces the amount of wiring used.

Software Defined Vehicle (SDV)

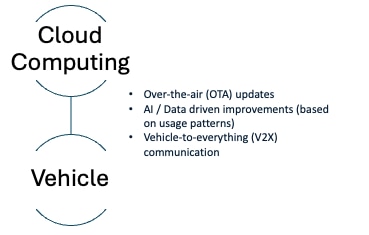

A Software Defined Vehicle (SDV) can be defined as a vehicle platform that has features defined by programming running on computer systems inside the vehicle. The features of the vehicle can be updated by software updates, instead of making changes to the mechanical hardware systems built into the car.

As more and more features like ADAS, infotainment and vehicle system monitoring are becoming expected by drivers today, a new way to deliver and keep systems updated is needed.

A SDV can personalize driver profiles allowing the vehicle to "remember" settings. Also, when interfaced with a vehicle's zonal architecture a SDV can monitor system performance and preventive maintenance.

There are several areas not normally found in traditional automobile development today that will need to be address especially in areas such as Cybersecurity and computer hardware to bring the SDV idea to widespread use.

digital.auto E/E Starter Kit

digital.auto is an open collaboration initiative shaping the future of Software-Defined Vehicles (SDVs). By providing a vendor-neutral, technology-agnostic platform, digital.auto accelerates innovation in SDV development, bridging the gap between OEMs, suppliers, and developers.

eFuse: Automotive Circuit Protection

In the rapidly advancing world of electronics, traditional mechanical fuses are becoming a limiting factor. As devices grow smaller, more complex, and demand higher power, a smarter and more dependable solution is essential. Enter electronic fuses (e-fuses)—the future of circuit protection.

EV Chargers

What is the future of electronics in an EV world? View Answer

As more transportation options make the switch to electrification (and remove the need for fossil fuels) there are several changes that need to be made both in terms of vehicle construction and infrastructure development.

Gas tanks are replaced by electrical energy storage and Internal Combustion Engines (ICEs) get replaced by electric motors, vehicles can be become simpler and easier to manufacture as major systems such as fuel distribution, mechanical linkages and exhaust are simply unneeded. With motion able to be generated closer to axel if not directly at the wheel and electrical power transferred by wiring from the battery pack.

Electrical power to recharge and power these vehicles may be from a green or low pollution source, however it may just as well be a coal fired power plant.

The other major concern is that while electrical vehicle recharging points are quicker than ever before they're still taking longer than using liquid fuels like gasoline to refill a tank.

As the era of the Internal Combustion Engine (ICE) comes to end, the era of Electrification in Transportation is starting. The transition is looking towards more efficient, lower pollution transportation solutions. The transition also brings new challenges, like charging infrastructure.

An Electric Vehicle (EV) charging station is a power supply with a connector able to fuel up an EV. These are sometimes referred to as a charging point.

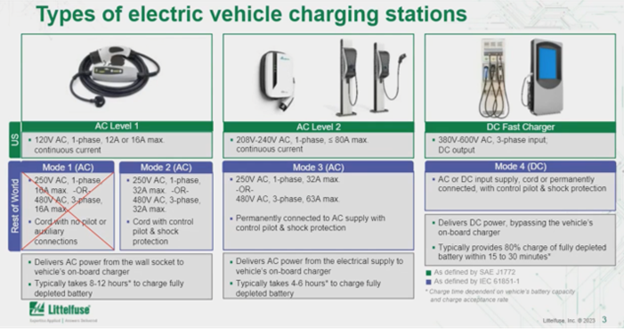

Charger Categories

- Level 1 – the most basic AC charging unit for EVs. While vehicle battery packs can only be charged with Direct Current (DC) electricity most vehicles have on board charging circuity that can convert AC power to DC power. The chargers are typically found at a home where parking overnight would not be unusual. Since level 1 only requires the use of a 110V or 120V input and outputs between 1 and 2 kilowatts of power, a standard electrical outlet can be used nearly anywhere.

- Level 2 – a step up from Level 1 chargers, with the ability to quickly charge vehicle battery packs within a few hours. Level 2 chargers typically requires a 220V or 240V hook up and can output between 3 to 19 kilowatts. Due to the increased power requirement and installation cost, level 2 AC chargers can typically be found in public spaces for EV charging or in private areas given a professional installation from an Electric Vehicle Service Provider (EVSP).

- Level 3 – Direct Current (DC) charging, "fast chargers". Direct Current Fast Charging are the highest power and fastest EV charging stations. While they can nearly charge a battery in less than 1 hour, they require an enormous amount of power to do so. Most Direct Current Fast Charging stations require at least 480 Volts and 100 amps, but some newer stations have the ability of 1000 Volts and 500 amps of electrical power. As such DC fast charging stations are commonly found only in public areas, such as rest areas or near shopping malls.

Image Source: Supercharged solutions for EV charging Webinar

Image Source: Supercharged solutions for EV charging Webinar

Plug Types

These plug types for EV Chargers are used in different regions and contain conductors for power and communication between the EV and the charger have defined standards for AC charging connectors. An Onboard Charger (OBC) is required within an EV for AC charging to be possible.Society of Automotive Engineers (SAE) and International Electrotechnical Commission (IEC)

Supercharged solutions for EV charging

The future of cars and mobility is electric. As the demand for electric vehicles grows, so does the need for reliable and safe charging systems.

Understanding Thermal Challenges in EV Charging Applications

As EVs emerge as the dominant mode of transportation, factors such as battery range and even quicker charging rates will play pivotal roles in sustaining the global economy. Enhancements in EV charging infrastructure will necessitate advancements across various domains, with thermal management standing as a key area.

Onboard and offboard chargers in eMobility applications

With an increasing number of electric powered vehicles on market and the roads: passenger cars, light vehicles, buses, trucks and construction and mining vehicles, there is a growing need in the eMobility industry for reliable, compact, efficient, and powerful products that help safeguard against outages disruptions,

How to Use Residual Current Monitors to Ensure Electrical Safety When Charging Electric Vehicles

Charging of the high-voltage battery of electric vehicles (EVs) translates to high mechanical stress for charging cables and connectors. If the insulation breaks and live metal parts are exposed, or shunts appear in the onboard electronics, life-threatening residual currents can occur in the EV user’s body.

Wide Bandgap Semiconductors for Transportation

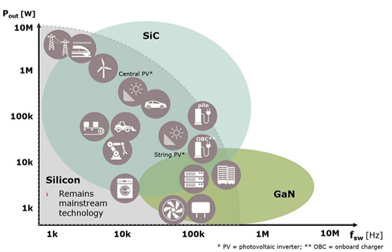

The future of electric transportation can be said to rest on the future of Wide Bandgap (WBG) Semiconductors. With their mix of higher working temperature and voltage when compared to traditional silicon semiconductor devices, wideband gap semiconductors can operate at higher power levels with lower losses.

The two most common wideband gap semiconductors on the commercial market are Silicon Carbide (SiC) and Gallium Nitride (GaN).

Advantages of SiC power devices

- SiC MOSFETs are unipolar devices that exhibit very low turn-on and turn-off switching losses. This property enables higher switching frequencies with lower losses, allowing the reduction of passive components and magnetics.

- High operating temperatures: silicon carbide offers superior thermal properties compared to silicon. SiC exhibits low leakage currents over a wide range of temperatures, allowing operation beyond 200°C. Simplified cooling and excellent thermal management are a bonus of this property.

Advantages of GaN power devices

- Low gate charge (QG) and on-resistance RDS(ON), which translate into lower drive losses and faster switching rates.

- Zero reverse recovery, resulting in lower switching losses and less EMI noise.

- High dv/dt: GaN can switch at very high frequencies and has 4x faster turn-on and 2x faster turn-off than SiC MOSFETs with similar RDS(ON)

How WBGs are impacting transportation systems

Higher operating temperature voltage and switching rates can directly improve transportation systems, here are some examples:

- Smaller and lighter weight electronics allow for compact and more efficient electric powertrains.

- Higher operating temperature and lower power losses allows for cooling systems to be smaller and lighter.

- Reduced power losses across components directly improve electrical efficacy.

Faster switching frequency, smaller components, and faster response times allows for more efficient use of battery power.

With smaller, lighter, more efficient electric drivetrains and related systems wideband gap semiconductor based electric vehicles have a very promising future in land, sea, and even air transportation.

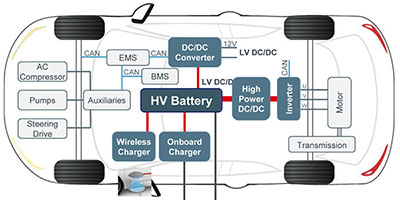

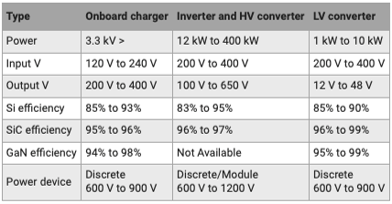

Systems within EVs reaping the benefits of WBG Semiconductors

There are some key systems, within EVs, to keep in mind in terms of benefits from WBG semiconductors. You'll find the WBG Semiconductors in the traction inverter, onboard charger (OBC) , and EV Charger.

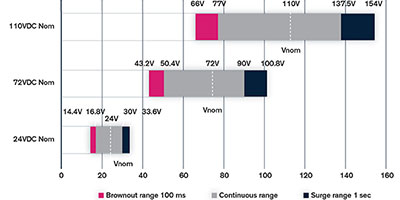

Specialized DC/DC Converters Meet the Unique Challenges of Railway Power Delivery

Designers specifying DC/DC converters for use in railways need to ensure those converters can perform reliably in confined spaces under difficult electrical, mechanical, and thermal stress conditions.

Wide Bandgap Semiconductors Are Reshaping the Transportation World

The entire transportation sector is undergoing a radical transformation, with internal combustion engine (ICE) vehicles gradually giving way to less polluting electric and hybrid cars and cleaner mass transportation solutions

In-vehicle networks (IVNs) and CAN Bus

In-vehicle networks are the common name for the set of connections that allows devices such as an Electronic Control Unit (ECU), cabin control, and Microcontroller Unit (MCU) in the vehicle to communication and exchange information.

CAN Bus

The CAN Bus standard started in the early 1980's and is a basic differential voltage signaled message-based protocol designed to allow devices and microcontrollers to communicate without a central host computer, this saves on cost and complexity. Fully described in ISO11898, classic CAN bus is for relatively low speeds of up to 1 megabit per second (Mbps) for a length of 40 meters or less and while developed nearly 40 years ago is not suitable for modern high bandwidth uses.

In modern applications CAN bus can be found in applications such as user interface controls and other medium bandwidth roles.

Variations on CAN bus that support higher data rate applications

- CAN Flexible Data Rate (CAN FD) was the first improvement with data rate up to 5 Mbps

- CAN Extra Long (CAN XL) improved data rates even further with speeds of up to 10 Mbps making it comparable to basic base10 ethernet connectivity and compatible with previous versions of CAN including CAN FD

Other protocols used in In-vehicle networks (IVNs)

- Local Interconnect network (LIN) Developed in the late 1990s as a cheaper and more cost-effective communication protocol to CAN Bus. With data rates of up to 20 kilobits per second (kbps), LIN is designed for Low-bandwidth applications where the complexity and cost of CAN bus is not needed.

- FlexRay is another IVN standard using synchronous communication that can provide higher data rates and bandwidth when compared to basic CAN bus, up to 10 Mpbs. FlexRay was developed by OEM automotive, and circuit manufactures as an answer to limitation in CAN speeds for higher data rate applications such as Advanced control and safety systems that require multiple high-speed sensor inputs.

- Automotive Ethernet was developed in response to increasing need for bandwidth for an Advanced Driver Assistance System (ADAS). Capable of speeds up to 100Mbps and allowing for Service-Oriented Architecture (SOA) software architecture like those used in Data Centers and with the ability to re-use of existing Internet Protocol (IP) software for other industries. The primary difference between automotive ethernet and regular ethernet can be found in the physical layer, with more robust cabling and interfaces to operate in the automotive environment of electrical interference.

The hybrid reality of modern In-vehicle networks (IVNs)

Most modern vehicles have several overlapping networks of CAN, LIN, and Ethernet connections depending on the connected hardware devices and data rate bandwidth required.

- LIN for simple electronic connections such as body electronics like side mirror and power seats positioning

- CAN for powertrain components, transmission positioning, and ABS control

- Ethernet for higher bandwidth like in cabin entertainment displays

Networking gateway devices can link these different networks together, allowing for a unified control system throughout the vehicle.

An Introduction to CAN Bus

The Controller Area Network, typically abbreviated to CAN or CAN Bus, is a serial, message-based communication protocol with the ability to connect numerous devices to exchange data on a single network.

The Basics of the Controller Area Network (CAN bus) and its Use in Automotive Applications

One of the classic IVNs is the Controller Area Network or CAN bus. Let’s take a look at it, and some example CAN bus transceivers.

How to Simplify the Test of CAN Bus Networks Using the Right Oscilloscope

One of the classic IVNs is the controller area network or CAN bus. CAN has been around for about thirty years, but it continues to develop.

Sensors for Transportation

With the increase in Advanced Driver Assistance Systems (ADASs) for safety and protection and the beginning roll out of Autonomous Driving vehicles, the need for sensors in transportation is only growing. Predictive safety systems can set off airbags and prepare for impact at the first signs of a collision, or in some case even prevent it all together.

Distance and position sensors

- Radar: radar sensors use radio waves to detect vehicles and other objects in the environment around the car. By measuring the time, it takes for a radar pulse to return to the receiver, the distance can be calculated.

- Lidar: distance is measured by sending a short laser pulse and recording the time taken between outgoing light pulse and the detection of the reflected light pulse.

- Ultrasonic: Measuring the time between sending out a short high frequency pulse of sound until it bounces off an object returns to a receiver Typically found in the front and rear bumpers useful for short range object detection or collision avoidance.

- GPS: By receiving GPS signals from orbiting satellites exact position can be determined within a few centimeters of accuracy with widespread and near global cover this is one of the most common types of system in use today.

Other sensors

Accelerometers, temperature, humidity, and optical sensors also get used within transportation. For more on these sensors see the Applications & Technologies page on Sensors.

Quick Guide to GaN FETs for LiDAR in Autonomous Vehicles

This article provides a brief introduction to LiDAR. It discusses applications and safety requirements before reviewing the challenges of designing automotive LiDAR, focusing on the high-current laser power loop.

Understanding Ultrasonic Sensors

In this article, we explain the principle of operation of ultrasonic sensors, consider their advantages and disadvantages, and review some of their most common applications.

Automotive Subsystems

An Advance Driver Assistance System (ADAS) is a safety feature in vehicles made up of many subsystems and technologies that assist the driver in driving and parking operations. While it not able to fully take over all driving responsibilities and tasks, ADAS does greatly increase driver safety and makes for a more enjoyable and safer driving experience.

An Advance Driver Assistance System (ADAS) is a safety feature in vehicles made up of many subsystems and technologies that assist the driver in driving and parking operations. While it not able to fully take over all driving responsibilities and tasks, ADAS does greatly increase driver safety and makes for a more enjoyable and safer driving experience.

As the demands for power in Electric Vehicles grow, the ability to recharge the vehicle's battery pack quickly and efficiently becomes more important. By implementing a high voltage, high current battery charging circuit, either onboard or at the charging station, the vehicle's battery pack can be recharged quickly with a minimum of downtime.

As the demands for power in Electric Vehicles grow, the ability to recharge the vehicle's battery pack quickly and efficiently becomes more important. By implementing a high voltage, high current battery charging circuit, either onboard or at the charging station, the vehicle's battery pack can be recharged quickly with a minimum of downtime.

An Anti-Lock Breaking System (ABS) is a safety feature in vehicles that help the driver maintain control during emergency braking situations. It does not necessarily make the car stop more quickly. Without ABS, more driver skill is needed to stop in unexpected situations, freeing the driver to concentrate on steering.

An Anti-Lock Breaking System (ABS) is a safety feature in vehicles that help the driver maintain control during emergency braking situations. It does not necessarily make the car stop more quickly. Without ABS, more driver skill is needed to stop in unexpected situations, freeing the driver to concentrate on steering.

Central Body Control (CBC) is subsystem responsible for power distribution and control across the vehicle body. Everything from Remote locks, power windows, and automotive lighting interacts with the CBC in one way. CBC also forms the network that allows for vehicle data and controls to communicate across the vehicle data bus to individual components.

Central Body Control (CBC) is subsystem responsible for power distribution and control across the vehicle body. Everything from Remote locks, power windows, and automotive lighting interacts with the CBC in one way. CBC also forms the network that allows for vehicle data and controls to communicate across the vehicle data bus to individual components.

Digital Radio is the next step in the in- car audio experience. With more compact and data rich digital transmissions replacing the standard AM/FM broadcast, digital radios can be more efficient, display more features and give a better listening experience with higher audio quality.

Digital Radio is the next step in the in- car audio experience. With more compact and data rich digital transmissions replacing the standard AM/FM broadcast, digital radios can be more efficient, display more features and give a better listening experience with higher audio quality.

Electric power steering (EPS) is a key subsystem for a safer and more responsive driving experience. Instead of using a mechanical and hydraulic connection from the steering wheel to the tires, an electric motor is used to control and assist the vehicle steering inputs from the driver. This smaller and more efficient solution allows for greater ease of use and higher degree of control.

Electric power steering (EPS) is a key subsystem for a safer and more responsive driving experience. Instead of using a mechanical and hydraulic connection from the steering wheel to the tires, an electric motor is used to control and assist the vehicle steering inputs from the driver. This smaller and more efficient solution allows for greater ease of use and higher degree of control.

Infotainment is the automotive subsystem for delivering audio and video entertainment to the vehicle passengers. Ranging from basic in-car radio to advanced touch screen displays, the infotainment subsystem covers everything from audio speakers, video displays and even wireless data connections.

Infotainment is the automotive subsystem for delivering audio and video entertainment to the vehicle passengers. Ranging from basic in-car radio to advanced touch screen displays, the infotainment subsystem covers everything from audio speakers, video displays and even wireless data connections.

The Automotive Instrument Cluster is primary user display for all vital information about the status of the vehicle. Speed, vehicle status, or warning lights can be displayed for ease of driver use. Newer vehicle models are transitioning away from individual analog gauge displays to have the whole of the instrument cluster be one large display panel, allowing for more responsive and interactive data presentation.

The Automotive Instrument Cluster is primary user display for all vital information about the status of the vehicle. Speed, vehicle status, or warning lights can be displayed for ease of driver use. Newer vehicle models are transitioning away from individual analog gauge displays to have the whole of the instrument cluster be one large display panel, allowing for more responsive and interactive data presentation.

As vehicle electrification continues, there is a need to convert the Direct Current (DC) electricity from the vehicle's battery pack into the Alternating Current (AC) electricity needed by the powertrain drive motors. The Main Inverter subsystem is the circuits that perform such a conversion allowing for higher efficiency and greater travel distance. The harsh environmental requirements and demanding electrical performance make this a critical piece of the electric vehicle design.

As vehicle electrification continues, there is a need to convert the Direct Current (DC) electricity from the vehicle's battery pack into the Alternating Current (AC) electricity needed by the powertrain drive motors. The Main Inverter subsystem is the circuits that perform such a conversion allowing for higher efficiency and greater travel distance. The harsh environmental requirements and demanding electrical performance make this a critical piece of the electric vehicle design.

A vehicle's Rear Vision System or back up camera is a safety feature to help eliminate a driver's rear blind spots while moving in reverse. A camera that outputs a live image to passenger cabin for the driver to see the immediate travel path of the reversing vehicle. As a mandated safety feature in new vehicles, back up cameras will make driving a safer and easier experience for all drivers.

A vehicle's Rear Vision System or back up camera is a safety feature to help eliminate a driver's rear blind spots while moving in reverse. A camera that outputs a live image to passenger cabin for the driver to see the immediate travel path of the reversing vehicle. As a mandated safety feature in new vehicles, back up cameras will make driving a safer and easier experience for all drivers.

Since most of the driver's time inside a vehicle will be seated position, it is vital that it be as comfortable as possible. Seat Control is the subsystem of electric motors and controls that allow users to adjust the position seat to their preference and allow for environmental control such as heated or air condition seats. While more complicated than older style controls, the comfort and degree of user control make it a priority for drivers.

Since most of the driver's time inside a vehicle will be seated position, it is vital that it be as comfortable as possible. Seat Control is the subsystem of electric motors and controls that allow users to adjust the position seat to their preference and allow for environmental control such as heated or air condition seats. While more complicated than older style controls, the comfort and degree of user control make it a priority for drivers.

The Start-Stop System found on most new vehicles that have internal combustion engines is a subsystem to help reduce emissions and save fuel. When the car sensors detect that it's no longer moving, it can deactivate engine, saving fuel. When the driver accelerates, the engine reactive. While requiring a stronger battery and electrical system the Start Stop System is a promising new way for efficiency.

The Start-Stop System found on most new vehicles that have internal combustion engines is a subsystem to help reduce emissions and save fuel. When the car sensors detect that it's no longer moving, it can deactivate engine, saving fuel. When the driver accelerates, the engine reactive. While requiring a stronger battery and electrical system the Start Stop System is a promising new way for efficiency.

Automotive Qualification and Grade

Who is the AEC? View Answer

As the consumer electronics market expanded in the late 1980 and early 1990's it became necessary to develop electronic specifications and part qualification standards for automotive circuits and systems components to ensure that automotive systems received the necessary parts that can withstand the harsh conditions and operate in automotive environments over a sustained time frame. The difference between driving home and an expensive repair bill could be the operation or failure of a single IC.

The Automotive Electronics Council (AEC) is an automotive industry organization originally established in the early 1990s by major automotive manufacturers Chrysler, Ford, and GM for the purpose of establishing common electronic part qualifications and standards. Today the AEC has expanded to include many different automotive component manufacturing companies and other industrial equipment manufacturers.

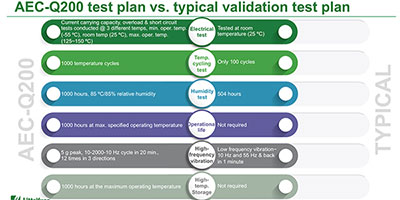

AEC standards

The AEC-Q series of standards are a set of qualifications and testing standards for all electronic components used in automotive applications. The specifications have been established by the Automotive Electronics Council (AEC) and are accepted by most automotive manufacturers across the globe. There are several testing conditions covered under AEC standards. Electrical performance, operating temperature range and thermal cycling, moisture and chemical resistance, vibration, physical stress testing, and solderability.

The testing areas, each with specific subcategories and testing regimes are as follows.

- AEC - Q100: Integrated Circuits (Chips)

- AEC - Q101: Discrete Semiconductors

- AEC - Q102: Discrete Optoelectronic Semiconductors

- AEC - Q103: Sensors in Automotive Applications

- AEC - Q104: Multi-Chip Modules (MCM)

- AEC - Q200: Passive Components such as Resistors, capacitors, and inductors

While the AEC-Q standard form the basis for testing and qualification some component manufactures go above and beyond those standards testing for more extreme conditions and operating environment and call them automotive rated, but the AEC-Q standards ensure minimum standards accepted by most automotive companies.

For more information, the AEC Public Documents page can be found here: AEC Documents

Do I need to use AEC-Q parts in my application? View Answer

Not necessarily, while AEC-Q rated parts are typically rated at high levels of ruggedness and reliability, especially in terms of thermal operating conditions and mechanical vibration to withstand automotive environment and applications, that also comes with a higher individual component cost and at times limited availability.

For most everyday consumer applications, regular commercial part will be more then suitable. Very rarely do everyday items face the conditions in an engine bay that has been running for hours.

AEC-Q200 Qualified Fuses Play a Critical Role in the Automotive Environment

AEC-Q200 Rev E sets rigorous stress tests for fuses to ensure their reliability in automotive environments.

The Selection and Use of FPGAs for Automotive Interfacing, Security, and Compute-Intensive Loads

FPGAs can be used to augment legacy microcontrollers and application processors in automobiles to enhance connectivity, processing performance, and security.

How to Ensure Circuit Protection, High Speed Data, and Power Conversion for eMobility Platforms

Use automotive qualified circuit protection, communications, and power conversion solutions to design sustainable and safe eMobility systems.

Automotive Applications Test a Power Chip’s Mettle

A look at the demands of cold cranking and solutions available to cope with the strain of starting a cold engine from STMicro, TI, and Linear Technology.

Reference Designs

Here at Digi-Key we have a wide range of reference designs from the top automotive component suppliers, allowing you to design and build the features of tomorrow's transportation solutions.

Brushed DC (BDC) motors

Brushed DC motors still play a vital role in automotive subsystems in everything from power steering, passenger cabin controls, and automotive engine control. Here is a small sample of reference design that use Brushed DC motors in automotive contexts.

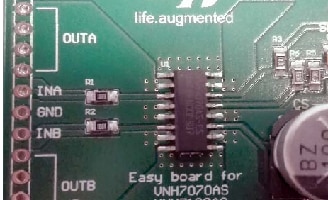

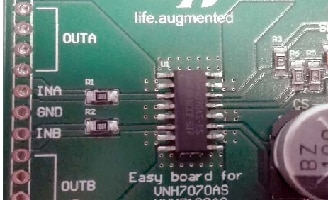

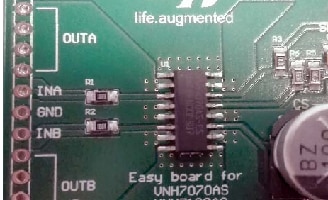

EV-VNH7070BAS: DC Brush Motor, 15A, 4 ~ 28V

VNH7070BAS is a full bridge motor driver intended for a wide range of automotive applications. The device incorporates a dual monolithic high-side driver and two low-side switches. This evaluation board comes preassembled with VNH7070BAS H-Bridge.

EV-VNH7070AS: DC Brush Motor, 15A, 4 ~ 28V

EV-VNH7070AS is a full bridge motor driver intended for a wide range of automotive applications. The device incorporates a dual monolithic high-side driver and two low-side switches. Both switches are designed using ST proprietary VIPower M0 technology.

EV-VNH7100BAS: DC Brush Motor, 15A , 4 ~ 28V

EV-VNH7100BAS provides you an easy way to connect STMicroelectronics VIPower M0-7 H-Bridge drivers into your existing prototype circuitry.

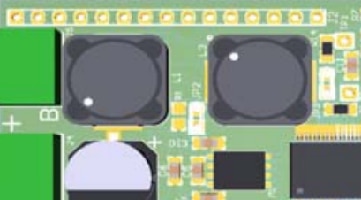

H-bridge motor driver

The rough world of Transportation and Automotive applications demand rugged, low power solutions with precise control and simple interfaces. That is where H Bridge motor controllers can shine in a variety of pump and engine control gates. Here are a few examples of Automotive qualified H Bridge reference designs.

EV-VNHD7012AY: 28V @ 38A Automotive H-bridge Motor Driver

VNHD7012AY is a full bridge motor driver intended for a wide range of automotive applications. The device incorporates a full protected dual high-side driver and the drivers and protections for the two external power MOSFETs in low-side configuration.

EV-VNHD7008AY: 28V @ 51A Automotive H-bridge Motor Driver

EV-VNHD7008AY provides you an easy way to connect ST VIPower M0-7 HBridge drivers into your existing prototype circuitry. This evaluation board comes preassembled with VNHD7008AY H-Bridge.

Image Source:

Image Source:  Source:

Source:  Image Source:

Image Source:  Source:

Source:  Source:

Source: