充分利用小型化布线系统,实现空间受限型设计

投稿人:DigiKey 北美编辑

2025-06-17

随着电子系统体积的不断缩小和功能越来越密集,设计人员面临着确保可靠互连的挑战。这一点在工业、医疗、军事以及航空航天领域尤为突出。在这些领域,不仅要求连接器结构紧凑,而且能够承受振动、热循环和其他应力。为应对这些挑战,设计人员需要那种兼具可靠性和空间效率的紧凑型互连解决方案。

本文将探讨此类互连的关键要求,包括端子密度、可靠的配接机制、耐热性以及信号和功率大小。然后介绍 Samtec 的多功能连接器生态系统,并说明如何使用该系统来满足这些要求。

紧凑布局中的连接器设计和导线布线

在为空间受限型设计选择连接器时,触头距离(即触头间距)是首要考虑因素。间距越小,连接器越紧凑。

连接器的多样化同样非常重要。例如,单排连接器可能是导线穿过狭窄空间的最佳选择,而双排连接器则可以提供更高的触头密度。同样,能将针座垂直或水平安装到印刷电路板(PC 板)上,使得在狭小间隙内工作变得更容易。

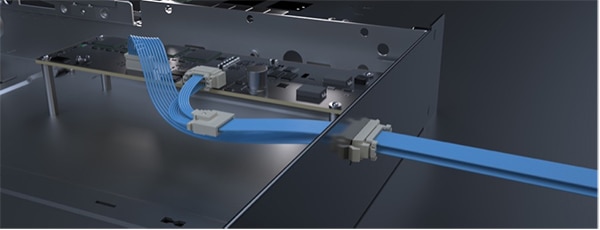

此外,还需在带状电缆和分立导线之间进行选择。虽然两种方案各有优势,但分立导线解决方案可提供更多的走线选择。这点在需要分支互连的应用中尤为重要,因为在此类应用中,一个电缆组件必须汇集来自设备内多个位置的导线(图 1)。

图 1:图中所示为分立式电线系统,用于简化导线聚集以及在单个组件中使用多种类型的连接器。(图片来源:Samtec)

图 1:图中所示为分立式电线系统,用于简化导线聚集以及在单个组件中使用多种类型的连接器。(图片来源:Samtec)

分立式电线的另一个优点是可以在一个组件中使用不同样式的连接器,以满足不同组件和子系统的要求。分立式电线还能在组件内灵活地组合电源和信号导线,并可选用色码来识别每根导线的用途。

连接器在苛刻条件下的保持力和热兼容性

运行过程中意外脱开,是威胁互连器件可靠性的主要因素之一。在较大型系统中,使用螺钉、紧固件或螺母等紧固件可以防止互连器件在机械应力作用下发生分离。然而,较小型系统往往空间不足,因此不适用这种方法。

在需要频繁插接的系统中,这些挑战更加复杂。无论是出于维护需要、现场升级还是重新配置,频繁连接和断开都需要安全、易用的保持方法。

为了解决这些问题,通常需要采用紧凑型锁止机构。这样,无需使用工具或辅助紧固硬件,徒手就能牢固地接插和断开连接器。

材料选择也是一个重要的考虑因素。连接器外壳和电线绝缘必须适合具体应用的环境条件,包括预期的工作温度范围以及任何适用的安全或监管要求。

小型互连器件中的电源传输和信号完整性

虽然尺寸是空间受限型设计的主要考虑因素,但小型连接器仍必须满足相应的电气要求。即使触头间距很小,互连器件仍需保证出色的信号质量,并能承载足够的电流和电压水平,以支持供电需求。

鉴于这些因素,触头和端子的设计就显得愈发重要。它们的几何形状应确保可靠的触头间距,所用材料应耐腐蚀,从而长期保持信号完整性。双弹性叶片设计在这种情况下尤其有用,因为这种设计有助于在宽温度范围和振动情况下始终保持稳定的触头压力,这对于在苛刻环境中避免信号丢失或电源中断至关重要。

适用于空间受限系统的高性能互连平台

Samtec 的 Micro Mate 分立式电线系统专为满足空间有限型应用需求而设计。Micro Mate 平台的显著特点是其 1 mm 触头间距,这使得权系列连接器封装都非常紧凑。解决方案适用于电缆到板、电缆到电缆和电缆到面板的应用,广泛地提高了设计灵活性。Gecko SL 系列的主要特点如下:

- 单排或双排配置,总触头数为 2 至 40 个,可满足各种信号和输入/输出密度要求

- 单闩锁或双闩锁机制,在机械压力环境下保证安全配接

- 额定电压高达 250 VAC 和 353 VDC,每个触头的额定电流高达 2.7 A,可同时支持信号和适度功率传输

- 双弹性叶片镀金触头系统,可在苛刻环境中确保稳定的连接和出色的信号质量

- 可选用特氟龙含氟聚合物护套,以增强耐化学性,并能兼容无卤或高温应用

除标准电缆组件外,Samtec 还针对定制布线提供组件级解决方案。这些解决方案支持创建定制化组件设计,最大限度地提高特定应用设计的空间利用率和布线灵活性。

使用现成的组件简化集成

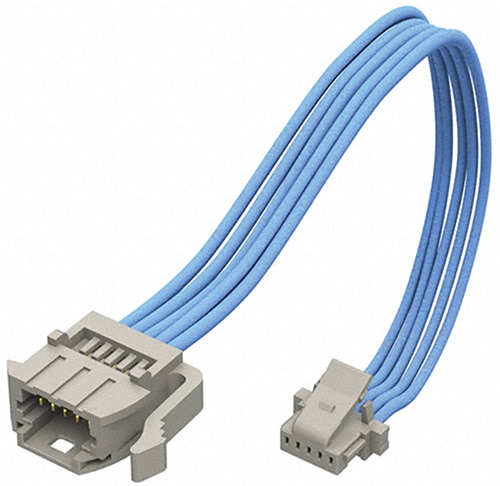

Micro Mate 电缆对电缆解决方案的典型产品如 S1SS-08-28-GF-06.00-L1(图 2)8 位单排组件,其两端均配有矩形插座。

图 2:S1SS-08-28-GF-06.00-L1 采用免工具正向闩锁机制,以确保连接牢固。(图片来源:Samtec)

图 2:S1SS-08-28-GF-06.00-L1 采用免工具正向闩锁机制,以确保连接牢固。(图片来源:Samtec)

在连接器外壳中内置了坚固耐用的免工具正向闩锁机制,是该解决方案的一个显著特点。即使在恶劣的工作条件下,这种闩锁也能确保连接可靠。在日常维护过程中,这种闩锁还能实现手动分离,无需使用螺钉或紧固件,这在难以使用工具的狭小空间内尤其有用。

电缆组件可与各种 Micro Mate 接插头配接,这些接插头包括一个集成锁扣斜面,可确保稳固的连接。 T1M-08-F-SV-L 就是一个典型示例(图 3)。这种水平表面贴装式扁平接插头支持电路板边缘安装,有助于最大限度地降低电路板上方的垂直高度。这种配置的绝缘高度仅为 5.51 mm,可支持较小的板对板间距,但不会影响机械坚固性。

图 3:T1M-08-F-SV-L 接插头是一种水平表面贴装解决方案,适用于垂直空间有限的应用。(图片来源:Samtec)

图 3:T1M-08-F-SV-L 接插头是一种水平表面贴装解决方案,适用于垂直空间有限的应用。(图片来源:Samtec)

免工具面板安装式解决方案

在无法使用安装螺钉或其他紧固件的情况下,面板安装式互连器件会带来其他挑战。卡扣式凸片可解决这一问题。

例如,T1PST-05-28-GF-02.0-A-T3(图 4)电缆到面板组件的特点是其坚固耐用的插座,集成了卡扣式凸片,可将连接器自动固定在面板开孔处,而无需专用的固定五金件。该组件可适应的面板厚度范围为 0.033 至 0.090 英寸 (in)。

图 4:T1PST-05-28-GF-02.0-A-T3 采用卡入式互连设计,可实现快速、免工具面板安装。(图片来源:Samtec)

图 4:T1PST-05-28-GF-02.0-A-T3 采用卡入式互连设计,可实现快速、免工具面板安装。(图片来源:Samtec)

由于无需使用紧固件,设计人员可以为指示灯、按钮或开关等其他功能性元件留出宝贵的面板空间。该组件还展示了 Micro Mate 平台的多功能性。在这种配置中,可为电缆选用特氟龙含氟聚合物护套,其额定温度范围为 -40°C 至 +125°C,适用于高温或无卤应用。

定制互连组件和工具支持

虽然现成的组件使用便捷,能够满足许多互连需,但空间受限型设计往往需要定制方案。例如,应用可能需要分支电缆走线或在单排和双排引脚布局之间过渡,以优化空间使用情况。这些技术对于手持式诊断工具或无人机子系统等复杂外罩来说特别有用,因为在这类外罩中,电线必须穿过不规则空间并绕过其他机电器件。

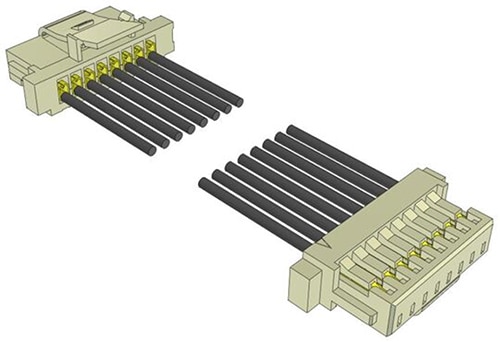

为满足定制要求,Samtec 提供组件级解决方案,使工程师能够从头开始构建 Micro Mate 组件或改造现有组件以满足其需求。例如图 5 所示的 IDT1-05 外壳插头。这种双排解决方案旨在最大限度地提高触头密度。

图 5:IDT1-05 外壳插头可用于创建双排布局中配有十根电线的定制组件。(图片来源:Samtec)

图 5:IDT1-05 外壳插头可用于创建双排布局中配有十根电线的定制组件。(图片来源:Samtec)

定制设计使用与工厂组装产品相同的镀金双弹性叶片触头。如图 6 所示,TC37R-01-GF 触头具有较大接触面积以及 0.076 微米 (µm) 镀金层,可确保低电阻和长期可靠性。

图 6:TC37R-01-GF 触头采用双弹性叶片镀金设计,电阻抵、可靠性高。(图片来源:Samtec)

图 6:TC37R-01-GF 触头采用双弹性叶片镀金设计,电阻抵、可靠性高。(图片来源:Samtec)

要保持稳定的连接质量,适当的工具必不可少。用于 Micro Mate 系列的 CAT-HT-309-2830-12(图 7)手动压线钳可帮助技术人员使用 28 或 30 AWG 电线构建定制组件,这些组件的机械和电气完整性可媲美工厂制造的解决方案。

图 7:CAT-HT-309-2830-12 手动压接器支持使用 28 或 30 AWG 电线可靠地手动组装 Micro Mate 互连组件。(图片来源:Samtec)

图 7:CAT-HT-309-2830-12 手动压接器支持使用 28 或 30 AWG 电线可靠地手动组装 Micro Mate 互连组件。(图片来源:Samtec)

结语

空间有限型系统需要采用在紧凑性、耐用性和电气容量之间达到平衡的互连器件。Micro Mate 分立式电线平台通过微型化的 1 mm 间距解决方案满足了这些需求。无论是连接内部子系统还是提供面板接口,该平台都提供了广泛的选择,支持灵活的高性能布线设计。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。