使用 TeSys VLS 隔离开关简化面板设计并提高安全性

投稿人:DigiKey 北美编辑

2025-06-18

大多数工业基础设施都需要隔离开关来安全隔离电路。无论是用于维护、紧急停机还是监管合规,这些开关都在确保系统安全和可维护性方面发挥着关键作用。Schneider Electric 的 TeSys VLS 隔离开关采用紧凑的模块化设计,额定电流为 25 A 至 125 A,符合 UL 508 和 UL 98 应用要求,常用于电机隔离、馈线分断和电气面板保护。

作为 TeSys 电机控制和保护产品系列的一部分,VLS 系列支持各种应用领域的工业和商业系统,包括材料搬运、暖通空调、泵、太阳能和采矿。这些开关提供 DIN 导轨式和门装式两种形式,可配置辅助触头块(如图 1 所示)、挂锁手柄、第四极和端子护罩等附件,以满足特定的安全和监管要求。

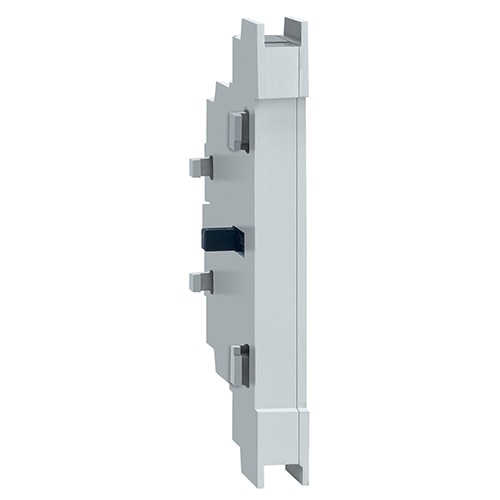

图 1. Schneider Electric TeSys VLS 辅助触头块提供状态指示或与安全和控制系统的接口。(图片来源:Schneider Electric)

图 1. Schneider Electric TeSys VLS 辅助触头块提供状态指示或与安全和控制系统的接口。(图片来源:Schneider Electric)

TeSys VLS 系列通过了 UL、CSA 和 IEC 标准认证,提供一致的安装尺寸和可扩展选件,可简化面板设计并降低了组件的变化。

本文回顾了 UL 508 和 UL 98 标准之间的实际差异,重点介绍了暖通空调、材料搬运、太阳能和能源等应用中的常见用例,并概述了 TeSys VLS 模块化架构如何实现灵活的安装和配置。同时还探讨了挂锁手柄、辅助触头和联锁装置等配件如何辅助实现安全功能和遵守挂牌标识协议。最后,解释了标准化组件和一致的外形尺寸如何帮助面板制造商和系统集成商简化外壳设计并降低库存的复杂性。

隔离开关和标准:UL 508 与 UL 98

工业隔离开关必须符合反映其在电气系统中预期功能的标准。UL 508 涵盖负载侧应用的电机控制器,而 UL 98 则定义了用于断开馈线的通用开关要求。这些标准的应用范围、性能要求和故障处理能力各不相同。

UL 508 适用于用于负载侧断开的手动电机控制器,通常用于隔离面板局部区域内的电机或设备。这些开关通常用于单个负载(如风扇或泵),不需要在完全故障条件时断开连接。UL 508 型号的短路额定电流为 5 kA,外形尺寸为 36 mm,结构紧凑,最适合空间有限的应用。

UL 98 适用于旨在断开整个馈线或作为面板主断开装置使用的通用开关。这些型号必须满足更严格的性能要求,包括 10 kA 故障电流额定值和更高的负载耐久性。UL 98 开关通常采用更大的 70 mm 外形尺寸,以支持更高的载流能力和故障中断能力。

UL 508 和 UL 98:TeSys VLS 技术规格

Schneider Electric 的 TeSys VLS 系列同时包括 UL 508 和 UL 98 认证选择,在保持机械尺寸一致的同时,提高了设计灵活性。UL 508 型号,如 TeSys VLS 25A 隔离开关(如图 2 所示)、32A 型号和 40A 变体,支持紧凑的面板布局和分支电路保护。

图 2:25 A 3 极 Schneider Electric TeSys VLS3P025R1 隔离开关通过 UL 508 认证,专为面板布局中紧凑型负载侧断开而设计。(图片来源:Schneider Electric)

图 2:25 A 3 极 Schneider Electric TeSys VLS3P025R1 隔离开关通过 UL 508 认证,专为面板布局中紧凑型负载侧断开而设计。(图片来源:Schneider Electric)

包括 TeSys VLS 63A UL 98 开关和 125A 型号在内的更大容量型号均通过了 UL 98 认证,可在配电系统中用于馈线级分断和主隔离。电流范围、短路额定值和端子容量等主要规格的详细比较见下表 1。

|

表 1:UL 508 和 UL 98 TeSys VLS 隔离开关规格比较。

TeSys VLS 系列的一个突出特点是 63 A 动作临界点,可同时提供 UL 508 和 UL 98 认证选择。系统设计人员可根据可用面板空间、所需故障中断能力和适用标准,在紧凑型 UL 508 开关和全尺寸 UL 98 开关之间做出选择。这种设计灵活性使其符合美国和国际法规,如 NEC 430.102 和 IEC 60947-3。

工业和商业应用

TeSys VLS 隔离开关产品系列支持广泛的工业和商业应用,从局部设备隔离到馈线级分断。VLS 系列提供了灵活的外形尺寸、认证选择和工作范围选择,可满足以下要求:

- 材料搬运:双认证 63A 选件,如适用于空间受限安装的紧凑型 TeSys UL 508 VLS 型号和适用于主隔离的 UL 98 级 TeSys VLS 开关,能够让系统设计人员优化输送机电机控制面板,可同时用于单驱动器隔离和市电配电。

- 暖通空调系统:如图 3 所示,TeSys VLS 125A 隔离开关等较大的 UL 98 级型号可支持商业建筑中屋顶设备的主面板断开或馈线级隔离,因为这些设备需要更高的中断等级和环境耐久性。

图 3:Schneider Electric TeSys VLS3P125D2 本体开关,125 A、3 极 UL 98 认证级隔离能力,用于馈线隔离和主面板断开。(图片来源:Schneider Electric)

图 3:Schneider Electric TeSys VLS3P125D2 本体开关,125 A、3 极 UL 98 认证级隔离能力,用于馈线隔离和主面板断开。(图片来源:Schneider Electric)

- 泵应用:TeSys VLS 63A UL 98 开关等中端型号可为离心泵、增压站和水处理系统提供可靠的隔离。UL 98 认证为直接在线电机启动提供了充分的故障保护,而挂锁手柄则支持市政设施的维护锁定协议。

- 太阳能安装:TeSys VLS 40A 隔离开关等紧凑型 UL 508 级开关可隔离单个 30 kW 逆变器或 DC-AC 转换器,在狭小的汇流箱和逆变器外壳中实现 NEC 690.15 快速关断功能。

- 采矿应用:重型 UL 98 型号(如 TeSys VLS 125A 隔离开关)可在矿物加工、输送系统和通风设备等恶劣条件下可靠运行。工作温度范围为 -25°C 至 +55°C,终端设计坚固耐用,可在对可达性和隔离性要求极高的地下和地面设施中可靠运行。

模块化结构和高效面板集成

TeSys VLS 隔离开关采用模块化结构,简化了面板设计、组装和维护。这些开关有 DIN 导轨式和门装式两种形式,支持多种外壳配置:

- 机械一致性:UL 508 型号(25 A 至 63 A)的统一宽度为 36 mm,而 UL 98 型号(63 A 至 125 A)的标准宽度为 70 mm。不同额定电流下的一致性允许重复使用安装模式和外壳布局,从而最大限度地减少了在多个应用中对定制机械设计的需求。

- 简化配件和库存:通用配件接口可降低物料清单的复杂性并简化库存。TeSys VLS 挂锁手柄适用于所有额定电流,而辅助触头块和端子配置在每个开关尺寸等级内保持一致。第四极、TeSys VLS 辅助触头和端子护罩等选件无需改装即可安装。TeSys VLS 机械联锁装置使用共用的安装接口,支持多个开关组合。

- 灵活的安装和外壳设计:门安装型包括轴延伸部分,可在外壳表面直接操作手柄,符合人体工程学和行业强制规范要求,方便关断和维护。这种设计方法能够让面板制造商和原始设备制造商减少外壳深度、统一钻孔模板并加快布局迭代,这在多品种、小批量的生产环境中尤为重要。

通过在当前额定值和认证等级中使用单一开关系列,工程团队可以简化产品开发,而生产团队则可以简化装配,减少功率等级和面板类型之间的差异。

安全、挂牌标识和可配置附件选择

安全性和合规性是任何隔离开关都要考虑的关键因素,尤其是在需要经常手动检修、维护或关断的系统中。TeSys VLS 系列通过提供模块化配件满足了这些需求,支持人员保护、标准合规以及与更广泛的安全架构集成。具体包括:

- 挂锁手柄:如图 4 所示,TeSys VLS 挂锁手柄外形紧凑,尺寸为 48 × 48 mm,单孔安装,防护等级为 IP65,可在有限空间内完成牢固的前面板安装。红黄相间的颜色编码支持 ISO 13850 紧急停机惯例要求,而一体式挂锁功能则为履行可靠的挂牌标识 (LOTO) 程序提供了便利。

图 4. Schneider Electric TeSys VLSH4S5R 旋转手柄,IP65 防护等级,一体式挂锁支持,用于前面板安全检修。(图片来源:Schneider Electric)

图 4. Schneider Electric TeSys VLSH4S5R 旋转手柄,IP65 防护等级,一体式挂锁支持,用于前面板安全检修。(图片来源:Schneider Electric)

- 状态和控制集成:TeSys VLS 辅助触头块提供额定电压为 690 V、电流为 10 A 的 1NO+1NC 触头,可实现实时状态指示或与 PLC 和安全继电器的集成。可选的提前断电变型支持安全关键型系统的定序功能和设备保护改进。

- 机械联锁:TeSys VLS 机械联锁装置可防止同时进行开关操作,便于按照 NFPA 79 和 IEC 60204-1 的规定执行顺序隔离程序。这些配件与额定电流为 16 A 至 40 A 的开关兼容,并支持电源转换和协调控制。

所有 TeSys VLS 组件均可在 -25°C 至 +55°C 温度范围内可靠运行(符合 IEC 60947-3),存储额定温度可低至 -40°C,可在全球市场上以 690 VAC 电压运行,安装高度可达 3,000 米。全系产品采用共用的接口尺寸和安装标准,简化了文档编制,简化了现场维护,且便于集成到符合安全标准的系统设计中。

结语

Schneider Electric 的 TeSys VLS 隔离开关集模块化设计、灵活安装选件与 UL 508/UL 98 双认证优势组合于一体,可简化工业面板的设计和合规。VLS 系列产品具有 63 A 的动作临界点,实现了空间与容量的优化、配件标准化以及 -25°C 至 +55°C 的工作温度范围,可在暖通空调、太阳能、泵和材料搬运等应用中提高安全性和可靠性并减少库存。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。