Standardized Testing for LEDs Extends to Lighting Fixtures

投稿人:电子产品

2013-12-03

LEDs are remarkably durable and rarely fail catastrophically. A more likely failure mode is fading until light output becomes unfit for the intended purpose. The decline in luminosity and change in color is very gradual, and potential LED “lifetimes” (the point at which the device is no longer fit for purpose) in excess of 50,000 hours are possible.

Standardized tests enable LED manufacturers to provide lighting engineers with quantitative estimates of the lifetime of their products without the companies having to go through the impractically lengthy process of testing the chips to failure.

The LED itself is but one small part of a solid-state lighting fixture. Once incorporated into a fixture, the lumen and color maintenance of the LED can be affected by factors such as heat, power supply fluctuations, and mechanical stress that were not present during the original test. However, lighting engineers had no standardized way of testing how severe the effect of these factors might be, and consequently no way of improving their fixture design to maximize the product’s lifetime.

The combination of a standardized test procedure and a method to use the data from the test to predict fixture lifetime has now been developed by the Illuminated Engineering Society of North America’s (IESNA) Testing Procedures Committee and is at final approval stage. This article explains how the test and predictive method works and how it will enable lighting designers to improve the longevity of their fixtures.

Testing LEDs

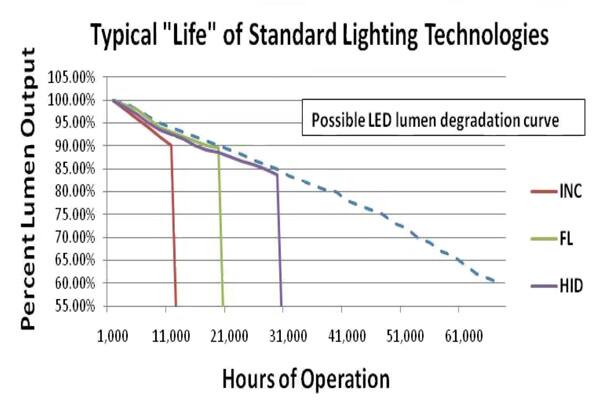

According to the U.S. Department of Energy, lighting lifetime is related to operating conditions (for example, ambient temperature and duty cycle), but typically a user might expect an incandescent bulb to last 1,000 hours and a halogen twice that long. In the case of fluorescent tubes, the ballast technology heavily influences the product’s lifetime; with cheap ballast, the tube may last for 20,000 hours increasing to 30,000 for more expensive types.

Of course, LEDs fail too. Sometimes this failure is catastrophic; for example, the epoxy resin used to encapsulate the die can overheat and expand, putting pressure on the device’s bonded connections until they give way. Electrostatic discharge (ESD) can cause immediate failure of the LED’s semiconductor junction. Another cause of catastrophic failure is the formation of metal whiskers, particularly in humid environments or where the LED is subject to mechanical stress, which bridge conductors causing a short circuit.

However, provided LEDs are driven and kept cool according to the manufacturer’s recommendations, the devices tend to be remarkably durable and only a small percentage of them actually fail catastrophically. A more likely outcome is that the LED will gradually fade until its light output becomes insufficient for the purpose for which it was intended (defined by the lighting industry as less than 70 percent of its output when new or “L70”).

This is in contrast to traditional lighting which is much more likely to fail catastrophically. (Traditional lighting can decrease in brightness by 20 to 30 percent during its lifetime, but the fixtures usually die well before the consumer notices (Figure 1).)

The combination of relatively few catastrophic failures and extremely gradual decline in light output means potential LED lifetimes in excess of 40,000, 50,000, or even 60,000 hours are not an unreasonable expectation.

However, in a commercial environment, manufacturers cannot be expected to subject their LEDs to a test lasting the best part of six years in order to prove their longevity claims. Instead, a shorter test, combined with a standardized extrapolation of trends derived from the test data, is used to determine how long an LED will last. The major LED makers routinely subject their products to the test, developed by IESNA and dubbed LM-80, “Approved Method for Lumen Maintenance Testing of LED Light Sources”.

Two U.S.-based laboratories, Pacific Northwest National Laboratory (PNNL) and National Institute of Standards and Technology (NIST), along with a group of six LED makers (including OSRAM and Cree), have produced a Technical Memorandum (TM-21, “Projecting Long Term Lumen Maintenance of LED Light Sources”) to define an extrapolation algorithm for lumen maintenance testing using the data from LM-80.

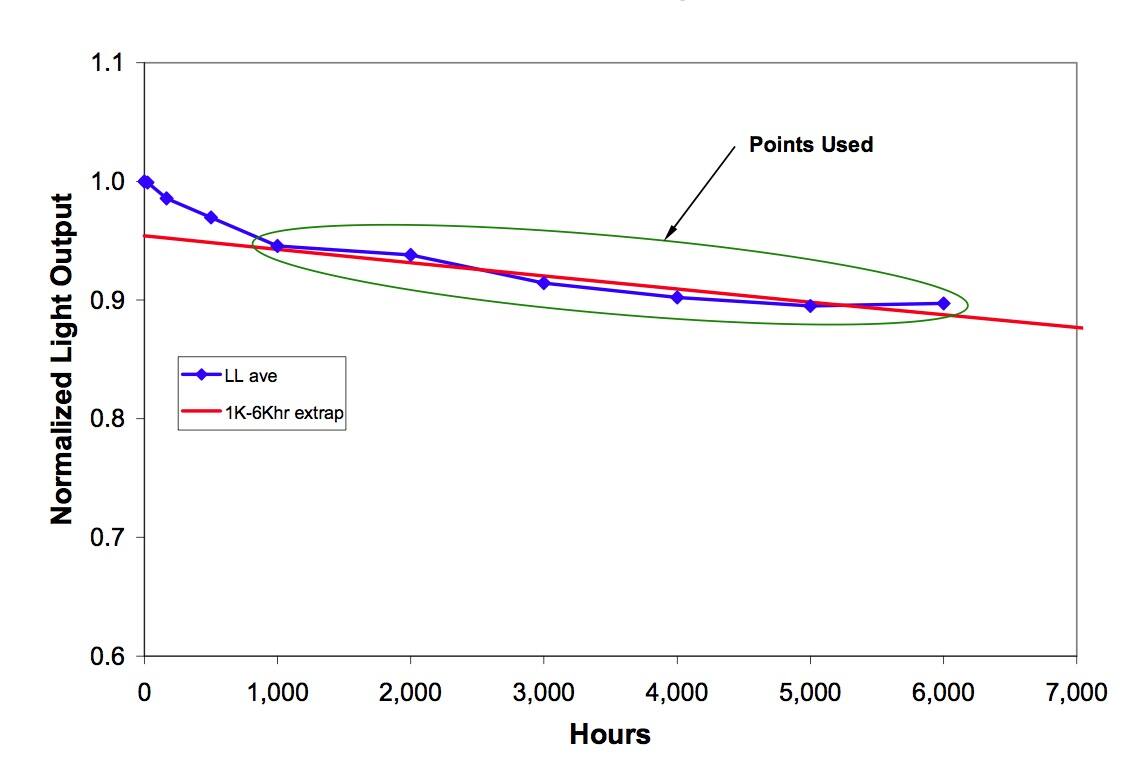

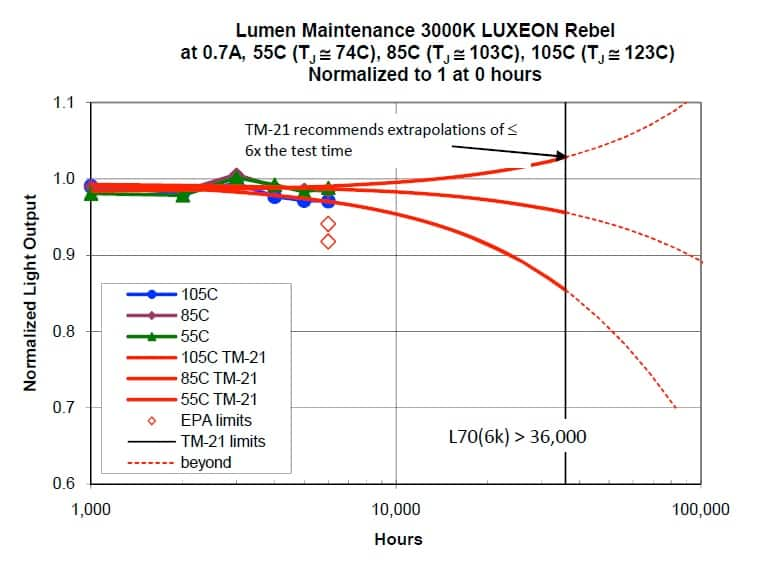

The algorithm ignores data from the first 1,000 hours, but uses it from the last 5,000 hours of the test (or final 50 percent of the data in the case of tests greater than 10,000 hours (Figure 2)). The data is then fit into an exponential extrapolation model using a least-squares curve method. The L70 extrapolation is then the lower of the resulting L70 time or six times the LM-80 test time. For example, with 6,000 hours of LM-80 test data, then L70 = 36,000 hours. With 10,000 hours of LM-80 test data, then L70 = 60,000 hours.1 (See the TechZone article “Determining LED Rated Life: A Tricky Challenge.”)

Commercial LEDs boast impressive L70 results. Philips Lumileds says its LUXEON Rebel white LED, a 105 lm/W (at 350 mA) device offering maximum luminosity of 226 lm (at 1 A), exceeds the Energy Star lumen maintenance requirements with an L70 figure in excess of 36,000 hours (Figure 3).

Cree and OSRAM say that their high-power devices like the former’s XLamp XM-L2, a 153 lm/W (at 700 mA) chip, and the latter’s OSLON SSL, a 125 lm/W (at 350 mA) chip, enable fixture makers using them to exceed Energy Star standards.

Limited to LEDs

The problem with the current test methods is that they only test the longevity of the LED itself. That is useful data, but when the chip is incorporated into a fixture there is much more that can go wrong. The power supply is one potential weakness, but perhaps more important is the efficacy of the product’s thermal management because excess heat is acknowledged as the number one “killer” of LEDs.

According to Cree, “the majority of LED failure mechanisms are temperature-dependent. Elevated junction temperatures cause light output reduction and accelerated chip degradation.”2

The primary cause of fading in an LED is due to degradation of the internal structure of the die itself, and this degradation is aggravated by high temperatures. In short, internal quantum efficiency, a measure of the number of electron-hole recombinations at the chip’s n-type/p-type junction that result in an emitted photon of a visible wavelength, goes down as dislocations in the chip’s crystal structure multiply. This is because the dislocations encourage non-radiative recombination and, as the name suggests, non-radiative combination does not result in an emitted photon.

LED chipmakers work hard to reduce the number of defects in the devices when new, but semiconductor manufacturing processes are not perfect and there will always be some faults. However, the most important factor under the control of the design engineer that does influence longevity by reducing multiplication of dislocations is junction temperature. (See the TechZone article “Understanding the Cause of Fading in High-Brightness LEDs.”)

A new test for LED light fixtures

Because the traditional lighting alternatives are mature products, more comprehensive lifetime data are available for these products and consumers are keen to see how LEDs compare. The good news is that solid-state lights are likely to shine brightly in such a comparison. The bad news is that manufacturers face the same problem that they faced with the chips themselves; testing to failure takes so long it is impractical.

For now, manufacturers of “drop-in” replacements for traditional lighting do their best to provide information about the long-term performance of their product based on the data for the LED(s) at the heart of their products. While using such test data to determine the lifetime of an LED lighting fixture is a good start, it is only going to provide an approximation because of the other factors that can shorten the fixture’s life.

LEDdynamics has introduced what it claims is the first commercially-available LED-based T8 fluorescent tube replacement. The device offers up to 1,900 lm at an efficacy of 94 lm/W with a Color Rendering Index (CRI) of 85. Called EverLED-VE, the fixture is available in 4,000 and 5,000 K standard color temperatures. LEDdynamics’ datasheet says EverLED-VE has a rated life of 10 years and consumers should expect zero percent failure to rated life.

Similarly, ROHM Semiconductor offers a drop-in replacement for incandescent bulbs, the R-B15L1 (Figure 4). The bulb produces 550 lm at a power consumption of 8 W (for an efficacy of 69 lm/W). The R-B15L1 operates directly from a 100 VAC input, and ROHM claims a “lifespan” of 40,000 hours.

What is really needed is an industry-standard test method to quantify the lifetime of any LED lighting fixture. IESNA has responded to this demand by adopting a similar approach to that used to test standalone LEDs. The resulting test procedure, LM-84 “LED Lamps, Engines and Luminaire Lumen and Color Maintenance Test,” is in its final approval stage with the IESNA committee.

The document describes the procedures required to obtain uniform and reproducible lumen and color maintenance measurements under standard operating conditions of an ambient temperature of 25 ±5°C and a lighting cycle of 11 hours on, 1 hour off.

However, LM-84 will not give the whole story. Like its counterpart LM-80, LM-84 only provides data on how well the fixture’s color and luminosity is maintained over a relatively short period. Unfortunately, it does not provide guidance or make any recommendation regarding predictive estimations or extrapolation for lumen or color maintenance beyond the limits of the actual measurements.

Sympathetic to the need to make predictions about how long an LED lighting fixture will actually be fit for purpose, IESNA is progressing toward an approach that will combine the LM-84 testing data on lighting fixtures with a new TM-28 document that standardizes methods for projecting the measured data over (much) longer periods. The approach parallels the way the LM-80 and TM-21 are used to predict standalone LED lumen and color maintenance.

The basic principles of TM-28 are likely to be the same as TM-21. The projection will be based on average test data, discounting the tested units that stop working during the test; the mathematical basis used in TM-28 will not deviate from TM-21, and the projection length must be based on a sample size and confidence level that makes practical sense.

One problem the committee faces is a paucity of data. When TM-21 was developed for LEDs, there were at least 40 sets of such data, some for LEDs that had been tested over 10,000 hours, which could be used to evaluate TM-21’s mathematical basis. Comparable LED luminaire test data are largely unavailable.

One solution under consideration is to mirror the requirement of LM-80 for 6,000 hours (or more) of testing and use the same algorithm for color and luminosity maintenance projection. That does leave open to question whether data from LED lamps being tested with less than 6,000 hours can still be used to make projections. The industry is keen to reduce the time and cost of such tests and there is a precedent: Energy Star allows 3,000-hour LED lamp test data to be used for prequalification.

The TM-28 working group has compared 3,000- and 6,000-hour LM-80 test data for LEDs and concluded there is sufficient correlation between the two to make sensible lifetime projections from 3,000-hour data. The algorithms used to project from these data are similar to those described in TM-21, but because of the shorter test duration, more conditional usage of the projection method will be added.3

What’s next for solid-state lighting tests?

Once published, documents LM-84 and TM-28 will be used together for LED lighting fixtures in the same way that LM-80 and TM-21 have been used for standalone LEDs. The new documents will enable the solid-state lighting industry to adopt a standardized approach to define the color and lumen maintenance of their products, helping consumers establish how LED lighting compares with traditional illumination.

However, because LED lighting is a far-from-mature industry, there is still more work to do. Other standards and test methods are focusing on specific product types and characteristics. The U.S.-based National Electrical Manufacturers Association’s (NEMA) SSL 7A-2013 document, “Phase-Cut Dimming for Solid-State Lighting: Basic Compatibility,” addresses a key issue for solid-state lighting by providing compatibility requirements for the use of dimmable LED products and forward phase-cut dimmers (the most common type).4

IESNA remains busy, too. Next up is likely to be LM-85 “IES Approved Method for the Electrical and Photometric Measurements of High-Power LEDs,” which addresses measurements for high-power LEDs that require a heatsink for normal operation, and includes white LEDs as well as single-color LEDs. Then there is TM-26 “Projecting Rated Life for LED Packages,” which will take the TM-21 L70 lumen maintenance information a step further by increasing the sample size and including catastrophic failures in the calculation to come up with an actual definition of “LED rated life” rather than just “lumen maintenance life.”

Further information on the products mentioned in this article can be found by clicking on the links provided to access product information pages on the DigiKey website.

References

- Street Lighting Consortium, 2011 Southeast Region Workshop, Tampa, Fl.

- “Cree XLamp XR Family LEDs,”Application Note: CLD-AP05.

- “The Latest in LED Lighting Test Methods and Standards,” Jianzhong Jiao, Ph.D., OSRAM Opto Semiconductors Inc., EPA Energy Star Products Partner Meeting, October 2012.

- “Holding SSL to High Standards,” SSL Postings, U.S. Department of Energy, June 2013.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。