The Basics of Current Sensors

投稿人:电子产品

2012-09-13

Current sensors are either open- or closed-loop. Open-loop current sensors measure AC and DC currents and provide electrical isolation between the circuit being measured and the output of the sensor (the primary current is measured without electrical contact with the primary circuit, providing galvanic isolation). Less expensive than their closed-loop cousins, open-loop current sensors are generally preferred in battery-powered circuits given their low-operating power requirements and small footprint features.

Closed-loop sensors measure AC and DC currents and provide electrical isolation. They offer fast response, high linearity, and low temperature drift. The current output of the closed-loop sensor is relatively immune to electrical noise. The Closed- Loop sensor is sometimes called a ‘Zero-Flux’ sensor because its Hall-Effect sensor feeds back an opposing current into a secondary coil, wound on the magnetic core to zero the flux produced in the magnetic core by the primary current. Closed-loop sensors are often the sensor of choice when high accuracy is essential.

Let’s now take a closer look at both types, starting with open-loop sensors.

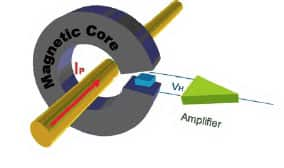

Open loop current sensors consist of a Hall sensor mounted in the air gap of a magnetic core (Fig. 1). A conductor produces a magnetic field comparable to the current. The magnetic field is concentrated by the core and measured by the Hall sensor. The signal from the Hall generator is low, so it is amplified, and it is this amplified signal that becomes the sensor’s output. Open-loop sensors normally have circuitry that provides temperature compensation and calibrated high-level voltage output. While they have a definite price advantage over closed-loop counterparts, their downside is that they can be prone to saturation and temperature drift. The drift can be minimized to some extent, however, by injecting a positive coefficient in the control current to reduce the drift in sensitivity over temperature.

Looking at Fig. 1, if the drive current in an open loop system is controlled using a constant current source and the differential Hall voltage is amplified, an output voltage proportional to the primary current only can be obtained by the electronics circuit.

One example is the HMS Series Open Loop Hall-Effect Surface Mount current Transducer by LEM (Fig. 2). The sensor features galvanic isolation between a primary and secondary circuit; 4300 V isolation test voltage; low-power consumption; a 12 mm, extremely low-profile; a single power supply +5 V; and fixed offset and gain.

Primarily used in industrial applications for AC variable speed drives, static converters for DC motor drives, battery supplied applications, uninterruptible and switched-mode power supplies, and power supplies for welding applications.

Another example is Honeywell’s CSLW Series Miniature Wired Open-Loop Current Sensors (Figure 3). The series incorporates an SS490 series of miniature ratiometric, linear Hall-effect sensors, and the sensing element is encapsulated in a PCB-mountable plastic package. The current sensor assembly is comprised of the sensor, flux collector, housing, and wire coil.

In this case, the wired, open-loop design has multiple turns for increased sensitivity. Other notable features include AC or DC current sensing, linear ratiometric output, current sinking or sourcing output for interfacing flexibility, low insertion loss, fast response time, compact size, and accurate, low-cost sensing. Applications include robotics, variable speed drives, industrial process control, motor control in appliances, HVAC, overcurrent protection and current monitoring of electronic circuits.

Fast response and high accuracy

In comparison to open-loop, closed-loop sensors measure AC and DC currents and provide electrical isolation, a fast response, high linearity, and low temperature drift. Their current output is impressively immune to electrical noise. Known for high accuracy, they are comprised of a Hall generator mounted in the air gap of a magnetic core, a coil around the core, and a current amplifier. The current carrying conductor placed through the aperture of the sensor produces a magnetic field that is proportionate to the current. This field is concentrated by the core and sensed by the Hall generator. The Hall generator is connected to the input of the current amplifier, which drives the coil. The current through the coil produces an opposing field, provided by the current through the aperture.

The output of this sensor is proportionate to both the aperture current and the number of turns of the coil. If the net primary current through the current transducer aperture is I, the number of turns in the compensation winding is N, and the current in the compensation winding is i, then at the zero flux condition I = Ni.

The output current of a closed-loop sensor is converted to a voltage figure by connecting a resistor to the output of the sensor and ground. Resistor value selection can result in scaling of the output.

An example of a current transducer with excellent accuracy, good linearity, and very low temperature drift is the LTS 25-NP from LEM (Fig.4). The device is a closed loop (compensated) multi-range current transducer using the Hall effect. Key features include:

- Unipolar voltage supply

- Isolated plastic case recognized according to UL 94-V0

- Compact design for PCB mounting

- Incorporated measuring resistance

- Extended measuring range.

Applications for the device are primarily in the industrial domain and include AC variable speed drives and servo motor drives, static converters for DC motor drives, battery supplied applications, uninterruptible power supplies, switched mode power supplies, and power supplies for welding applications.

Summary

While both types of sensors can be economical depending on the application requirements, open-loop sensors provide the best cost advantage in the high current ranges (over 100 A). They are also the smallest size and weight. They maintain constant power consumption, no matter the sensed current. The price advantage of open sensors may only be realized for applications where temperature variation can be restricted.

Closed-loop current sensors, on the other hand, are more suitable for commercial and industrial applications, where they are commonly found. These sensors have the highest accuracy at ambient and high temperature. They are ideal for noisy environments and their output is easily converted to voltage.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。