How New Flicker Recommendations Will Influence LED Lighting Design

投稿人:电子产品

2016-01-05

Research has shown that flicker––a variation of luminance over time––from lighting occurring in a certain frequency range can be detrimental to health. While the problem was addressed for incandescent and fluorescent lighting, it has reappeared as a challenge for design engineers since the introduction of LEDs for mainstream illumination.

But now, after extensive investigation, the U.S.-based Institute of Electrical and Electronics Engineers (IEEE) has published recommended practice for eliminating perceptible flicker in LED lighting. Entitled “Recommended Practice for Modulating Current in High-Brightness LEDs for Mitigating Health Risks to Viewers,” IEEE Std. 1789-2015 explains what’s known about flicker in LED lighting and provides guidance that can help manufacturers design products that minimize possible flicker-associated health and productivity effects.

The primary source of flicker in an LED-based product is the power supply or “LED driver.” LED-based products with well-designed drivers can deliver light with minimal flicker, but doing so can increase the cost and/or size of the driver circuitry. For example, smaller products such as MR16 replacement lamps are more susceptible to flicker due to size limitations on the driver.

This article takes a look at why flicker should be controlled, describes the IEEE recommendations and considers a selection of contemporary drivers that could be employed as the basis of a flicker-free power supply.

Driving LEDs

All conventional light sources, even the venerable incandescent bulb, produce a variable (or modulated) output. The source of the modulation––which design engineers commonly refer to as flicker, although other terms, for example, flutter and shimmer are used––can come from either photometric or electrical sources.

Photometric flicker is a function of the light itself and can be caused by things like the make-up of the filament in an incandescent bulb or the type of phosphor used in a fluorescent tube. In the case of LEDs, while there can be some sources of photometric flicker, the effect is dwarfed by electrical flicker. Electrical flicker is a result of modulation caused by the AC source, and is compounded by noise or transient events on the AC distribution lines.

LEDs require a DC voltage at a constant current to operate (even those that are labelled “AC LEDs” (see the DigiKey article “AC LEDs Gain in Popularity”). Silicon manufacturers such as Analog Devices, Fairchild Semiconductor, Infineon Technologies, Linear Technology, Maxim Integrated, and Texas Instruments (TI) supply AC-to-DC converters teamed with DC-to-DC regulators to regulate, for example, 110/120 V, 50/60 Hz mains current to the low-voltage, steady current demanded by the LED. These regulators are based on proven power supply topologies that are then optimized for use with LEDs and are collectively categorized as LED drivers.

LED light output rises linearly with increasing drive current. Figure 1 shows a graph from the datasheet of a Lumileds LUXEON 3535L cool-white LED illustrating this relationship. This LED is a mid-power device designed to operate at up to 200 mA and which produces 42 lm at 3.05 V/100 mA (with an efficacy of 138 lm/W).

Figure 1: Normalized light output vs. forward current for Lumileds LUXEON white LED.

The gradient of the relative light output versus forward current curve is steep; increasing the output by just +/- 10 mA around the 100 mA operating point varies the light intensity by +/- 10 percent. Even more modest fluctuations in forward current results in flicker that can be perceived by humans.

There are several sources of current ripple at the output of a DC-to-DC converter used to drive LEDs, including the AC mains (50/60 Hz), full-wave-rectified mains (100/120 Hz), and, if a switching regulator is being used to facilitate the regulation (which is often the case), the switching frequency of the power electronics (a few hundred KHz up to several MHz). The operational frequency of pulse-width modulation (PWM) used to dim the LED (several kHz) can also influence current ripple at the output of the regulator. Better regulators exhibit smaller current ripple, but typically at an increase in cost, complexity, and space.

Why is flicker a problem?

Flicker from light sources is typically very subtle: it normally does not lead to a noticeable sensation in the human observer even though the brain does perceive the light variation. Consequently, many people who suffer from flicker sensitivity may not be aware that lighting is the reason for their malaise. To make things even more difficult, humans are not all equally sensitive to the effects of flicker. Those that are more sensitive include children and people who suffer from migraines, autism, or epilepsy.

Flicker from lighting is at best annoying and at worst detrimental to health. Flicker can cause eyestrain, blurred vision, and impairment of performance during sight-related tasks. For 10 percent of the population flicker triggers migraines, and other groups are prone to debilitating effects.

These effects first came to the attention of lighting engineers when mains-powered fluorescent tubes replaced incandescent lights. During the 1970s and 1980s it was discovered that while barely imperceptible, flicker in the 70 to 150 Hz range did cause productivity losses and health effects. The low-frequency, magnetic ballast that were needed to limit the current during the tube’s operation caused the flicker. By moving to high-frequency ballast manufacturers eliminated the problem by shifting any flicker to a frequency range beyond that perceptible to humans.

However, as LEDs penetrated mainstream lighting applications the problem of flicker returned. There are two factors of solid-state lighting technology that can make the problem particularly acute: the marked sensitivity to variations in driver current (described above) and a lack of “persistence” when the drive current drops.

Persistence is a measure of how quickly the light output from a source fades when the current drops. Highly persistent sources such as incandescent lights continue to emit a relatively large amount of light between voltage peaks, effectively “bridging the gap” and lowering the percentage flicker. Fluorescent tubes, while not as good as incandescent lights, also exhibit high persistence. In comparison, LEDs exhibit virtually no persistence, instantly darkening once the current drops. This is true for both red, green, blue (RGB) LED combinations and white LEDs which combine a blue LED with an yttrium aluminum garnet (YAG) phosphor.

The insidious effects of imperceptible flickering in the 70 to 150 Hz range are not just a function of frequency; physical and physiological factors also play a big part. For example, bright light is worse than dim, and the difference between “bright” and “dark” parts of the lighting pattern are important (a light that goes completely dark during the “off” part of the cycle––for example, a poorly-persistent LED––is worse than one which only partially dims); and the position of the light source on the retina is important, as light sensed by the center is worse than that falling on the periphery. [¹]

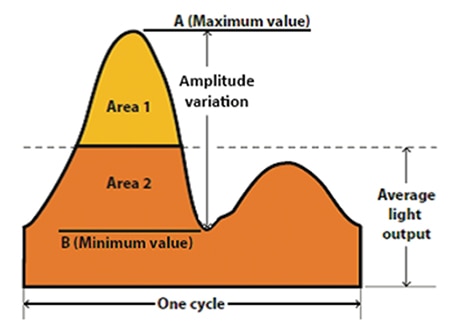

The Illuminating Engineering Society of North America (IESNA) has come up with a definition that defines flicker in terms of “percent flicker” and “flicker index” in The IESNA Lighting Handbook (now in its tenth edition). Figure 2 shows how the metrics are defined.

Figure 2: Periodic waveform characteristics used in the calculation of flicker metrics. (Source: the IES Lighting Handbook, 10th Edition)

Percent flicker is a relative measure of the cyclic variation in output of a light source (i.e., percent modulation). This is also sometimes referred to as the “modulation index.”

From the figure: Percent flicker = 100 x (A – B)/(A + B)

Flicker index is a “reliable relative measure of the cyclic variation in output of various sources at a given power frequency. It takes into account the waveform of the light output as well as its amplitude,” according to the IES handbook. The flicker index assumes values from 0 to 1.0, with 0 for steady light output. Higher values indicate an increased possibility of noticeable lamp flicker, as well as stroboscopic effect.

Again, from the figure: Flicker index = Area 1/Area 1 + Area 2

(For further information see the DigiKey technical article “Characterizing and Minimizing LED Flicker in Lighting Applications”.)

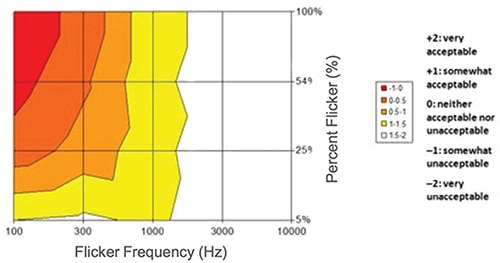

Figure 3 illustrates the results of tests on how volunteers perceive the acceptability of flicker frequency and percent flicker.

Figure 3: Human acceptability of flickering light sources. (Courtesy of the U.S. Department of Energy)[2]

The new recommendations

IEEE Std. 1789-2015 makes recommendations for managing the potential biological effects of flicker at two defined risk levels. While operating outside these levels does not mean there will be biological effects, if an engineer designs a product that operates within the recommendations he or she can be sure that the risk of biological effects is limited to defined levels.

Determination of which level the product is designed to meet does depend on many factors, including characteristics of the target consumer group, exposure time, types of tasks undertaken in the illuminated area space, and the individual’s sensitivity to flicker. Naturally, the designer is also faced with trade-offs generated by the product’s specification, including product cost, size, and lighting performance.

For general applications the standard recommends keeping the percentage flicker below 5 percent at frequencies below 90 Hz to prevent seizures (seizures aren’t triggered at frequencies above 70 Hz).

In addition, to lower the risk of other biological effects, the standard recommends applying the following formulas to determine the maximum percent flicker:

- At frequencies below 90 Hz, maximum percent flicker = frequency x 0.025 [for example, at 80 Hz, the maximum percent flicker is 80 x 0.025 = 2 percent]

- At frequencies between 90 and 1250 Hz, maximum percent flicker = frequency x 0.08 [for example, at 250 Hz, the maximum percent flicker is 250 x 0.08 = 20 percent]

- At frequencies above 1250 Hz, no restrictions on the percent flicker. (Note: this is the minimum allowable frequency for basic pulse-width modulation (PWM)-based dimming.)

To prevent the other biological effects, the standard recommends applying the following formulas to determine the maximum percent flicker:

- At frequencies below 90 Hz, maximum percent flicker = frequency x 0.01 [for example, at 50 Hz, the maximum percent flicker is 50 x 0.01 = 0.5 percent]

- At frequencies between 90 and 3000 Hz, maximum percent flicker = frequency x 0.0333 [for example, at 1200 Hz, the maximum percent flicker is 1200 x 0.0333 = 40 percent]

- At frequencies above 3000 Hz, no restrictions on the percent flicker. (Note: this is the minimum allowable frequency for basic PWM-based dimming.)[3]

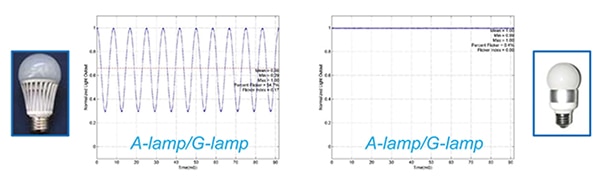

Figure 4 shows two examples of LED lights operating at a frequency of 110 Hz. The recommendations state that to prevent biological effects the percent flicker should be kept to below 110 Hz x 0.333 = 3.7 percent. The first example, with a percent flicker of 54.7 percent falls well short of the grade. The second example is well within the recommendations exhibiting a percent flicker of just 0.4 percent.

Figure 4: Example of LED lighting that (left) fails to meet IEEE Std. 1789-2015 recommendations for flicker and (right) an example that meets the standard. (Courtesy of the U.S. Department of Energy)

Sourcing compliant LED drivers

There is no doubt that given an unlimited budget and plenty of space within the product, a lighting designer can source an LED driver that will never cause perceptible flicker. However, designers are rarely blessed with such a forgiving specification. Worse yet, consumers increasingly demand seamless dimming which can cause flicker in a system that is flicker-free in an undimmed state or exacerbate flicker that is already present.

However, there are a wide range of LED drivers from across the cost and size spectrum that, with careful selection should ensure that any flicker generated is either too small or at too high a frequency to be perceptible to the consumer according to the IEEE Std. 1789-2015 recommendations. The recommendations are too new for manufacturers to have designed products specifically to meet them; but flicker prevention has been on the power supply vendors’ radar for several years now so many LED drivers can facilitate a power supply that meets the new standard.

For example, Linear Technology offers a wide-input range LED driver with built-in 10:1 dimming. The LT3590 is a fixed-frequency DC-to-DC converter that operates as a constant-current source for driving ten LEDs in series (Figure 5). The device operates from a 4.5 to 55 V input range and a 35 V output at up to 80 mA per channel. The company claims the high switching frequency permits the use of small, low-impedance ceramic capacitors that result in low-output current ripple.

Figure 5: Linear Technology’s LT3590 has been designed to drive a string of 10 LEDs.

TI supplies a range of LED drivers. One notable example is the TPS92510, an LED driver that operates from a 3.5 to 60 V input and supplies up to 1.5 A per channel. The company says that to improve performance during line and load transients, the device implements a constant frequency, peak-current mode control which reduces output capacitance and simplifies external frequency compensation design. The chip promises +/- 3 percent LED current accuracy, limiting current fluctuations.

For its part, Maxim Integrated offers its MAX16834, a current-mode LED driver for switching power supply topologies. The chip operates from a 4.75 to 28 V input for a maximum 28 V output. In addition to driving the power transistor, the device drives a PWM switch used for LED dimming. The chip also features a programmable switching frequency (100 kHz to 1 MHz) which not only allows design optimization for efficiency and board space reduction, but also provides flexibility for minimizing current ripple and flicker. Because of its compact size (4 by 4 mm) and high degree of integration, the LED driver is suitable for applications where space is tight such as MR16 light fixtures.

Selection of an LED driver that limits current ripple is a good basis for a lighting design, but it should be remembered that while the power supply is a major source of flicker, it is not the only cause of problems. It’s likely that the flicker performance of the end product will need to be established by photometric testing to ensure that the whole package meets the recommendations under all operating conditions.

Flicker in the spotlight

As LED lighting makes significant inroads into the mainstream lighting market, the health effects of flicker are likely to receive greater consumer attention. By adhering to the recommendation issued in IEEE Std. 1789-2015, lighting designers can ensure that their products are demonstrably non-detrimental to health. Meeting the recommendation might add some cost to the end product because it will require sourcing a well-designed LED driver, but it has been shown that the consumers are prepared to pay more to safeguard health.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

References:

- “A Review of the Literature on Light Flicker: Ergonomics, Biological Attributes, Potential Health Effects, and Methods in Which Some LED Lighting May Introduce Flicker,” IEEE Standard P1789, February 2010.

- “What You Need to Know about LED Flicker and Dimming,” Michael Poplawski, U.S. Department of Energy, May 201.

- “A Much-Needed Recommended Practice for LED Flicker,” SSL Postings, U.S. Department of Energy, June 2011.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。