How to Choose the Right Power Supply for Your LED Lighting Project

投稿人:DigiKey 欧洲编辑

2013-05-07

With the proliferation of high-brightness LEDs designed to provide replacement lamps for commercial and domestic lighting there comes an equal, if not greater, proliferation of power supply solutions. With hundreds of products from dozens of manufacturers, it becomes a question of how to make sense of all the permutations of input / output voltages and output current / power ratings, to say nothing of the mechanical dimensions / termination types and the many other features for dimming, remote control, and circuit protection that are offered. This article aims to unravel the mysteries of the different types of LED power supplies and how they operate in order to ease the selection process.

To help understand the various solutions, the article will reference a number of products readily available from DigiKey, including AC/DC converter modules from Emerson Network Power and CUI Inc., buck modules and buck-boost modules from RECOM Power, and boost boards from TDK-Lambda and Microsemi.

Understand your LED lighting application first

In order to determine the type of power supply best suited for a particular lighting project, it is first necessary to understand the nature of the application, i.e. what form the LED lighting will take and where and how it will be deployed. There is no unique segmentation, but the ‘where’ usually relates to the broad market, while the ‘what’ or ‘how’ is more about the function or characteristic of the lighting. Typical market segments for lighting are retail, industrial, and architectural along with the terms ‘indoor’, covering commercial and residential use, and ‘outdoor’ for street lighting and building illumination. Already there is an overlap in these descriptions, so it is probably more helpful to explore a few examples in a little more detail to appreciate what they may require from a power supply.

Retail applications can range from space lighting to window, shelf, or display cabinet lighting including point-of-sale displays and signage. The lighting needs to be of high quality with a consistent color for showing products to best effect. Ambient lighting will provide unobtrusive background illumination, while accent lighting will be more obvious in highlighting a particular product or display area. Cabinet lighting usually needs to be concealed, so as not to detract from the product, whereas ambient lighting is less likely to be in the customer’s line of sight, e.g. illumination from ceiling fixtures. Lighting in retail outlets is often operating for long periods of time, so high reliability and good efficiency, to reduce running costs and temperatures, are important requirements for the power supply. Because of its reduced heat output, low-power LED lighting is proving popular in refrigerated display cabinets; clearly moisture-sealed supplies with low heat dissipation are likely to be equally important for powering such lights.

Outdoor applications embrace street lighting, including related traffic signals and signage, and building illumination, which covers all forms of external lighting such as safety/security lights, floodlights, and other decorative lighting such as up/down and color-wash effects. A key specification for any power supply unit (PSU) used for outdoor lighting will be its IP rating, necessary to provide an appropriate level of protection against moisture, water spray, and even immersion as well as against dust and solid objects. One of the main drivers for the adoption of LEDs for outdoor lighting is their long lifetime, which enables a ‘fit and forget’ approach to installation and maintenance. Consequently, it is important that the power supply chosen for outdoor LED lighting also offer a high-reliability solution for long lifetime and low maintenance.

Commercial and residential uses for indoor LED lighting are myriad. The starting point for LEDs is the replacement of more established light sources such as incandescent or fluorescent lamps. This can include conventional ceiling and wall lights and similar lighting fixtures, as well as table/desk lamps and the illumination of pictures and ornaments. However, LED technology offers more than just a means of energy saving, with the opportunity to readily embed LED lights in floors, staircases, and walkways for both safety and decorative effect, and to implement display lighting similar to the retail lighting applications described above. Dimming is a common requirement for domestic lighting, and power supplies that provide this capability are clearly important. Many LED lights also offer mood-enhancing or color-changing effects, and these require power supplies with multiple outputs that can be individually controlled to provide the desired ambience or color balance. Other requirements for power supplies for indoor applications will vary widely according the type of lighting, and whether it is built-in or a standalone unit. The challenge may be physically accommodating the supply, especially where LED lighting is being retrofitted into the existing structure of a building, so its size and form factor may be important. Issues of accessibility once installed may also dictate a unit designed for high-reliability and long life.

Understand what to look for when selecting your LED power supply

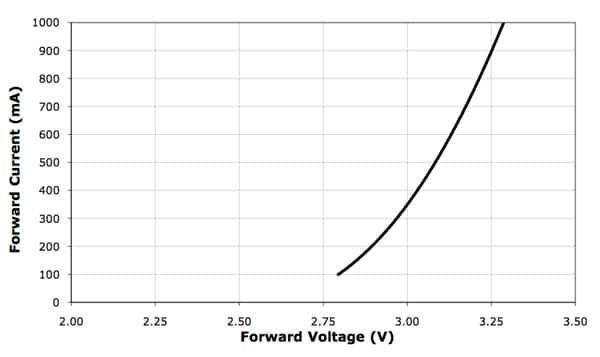

Understanding your LED lighting application is a good start, but determining the ideal power supply also requires a little more insight into the operation of LEDs before we can narrow down the choices available. A light emitting diode (LED) is a semiconductor device that emits light when a current flows across the P-N junction in the device. The forward voltage (i.e. positive bias across the junction) for optimum performance is typically around 3 V, but the relationship of voltage to current is non-linear. Therefore, as can be seen in Figure 2, the LED starts to turn on at a lower voltage but rapidly draws a much higher current as the voltage increases above its nominal rated value. The relationship between relative luminous flux (a measure of the light output) and forward current is also non-linear so, while driving an LED with a higher current will increase the light output, this is generally less efficient than using multiple LEDs to achieve the same result. However, analog dimming of LEDs over a limited brightness range is possible by varying the drive current up to and sometimes even beyond its nominal rating. However, as we will see later, there are several other methods for implementing dimming. Another characteristic to be aware of is the effect of temperature, which, as it increases, results in a decrease in the forward voltage (for a given forward current) and less efficient operation.

Given the above characteristics, the conventional approach to driving LEDs is by controlling the current through the device. The simplest method employs a series resistor to limit current such that

where IF = forward current

VCC = supply voltage

VF = forward voltage (across one or more LEDs in series)

R = series resistor

Hence a fixed or constant voltage (CV) power supply can be used to drive LEDs either singly, in a series string (provided VCC > VF) or in parallel (provided that the current in each parallel path is limited by a series resistor). However, the importance of driving LED lights with a defined current has pushed LED power supply manufacturers to develop comprehensive ranges of constant current (CC) power supplies, such as the VLED15-230-350 unit from CUI Inc. shown in Figure 3. This takes an AC mains input and delivers a regulated 350 mA DC output of up to 48 V, which is sufficient for a series string of up to sixteen LEDs. Further developments in power supplies for LED lighting have resulted in designs that combine CV and CC modes of operation in one unit. These products, like the Emerson Network Power LDS70-58-U01 shown in Figure 1, provide a versatile solution and simplify inventory management, which may be important for diverse commercial lighting installations and for subsequent maintenance.

It is the improved performance and increased light output of white, single-chip LEDs that has enabled them to replace lights that are more traditional. So, while the power rating of an LED bulb may be a fifth or less when compared to an incandescent light providing the same light output, the power requirements still range from a few watts to a hundred watts or more for floodlights or streetlights. Clearly, the power handling capability of an LED supply needs to be sufficient to cope with the intended load. While it is good practice to design a lighting system with some margin or tolerance to allow for variations in load conditions, most of the off-the-shelf power supplies include protection against conditions such as overcurrent, overvoltage, overtemperature, or short circuits. These protection features also contribute to safety specifications such as UL and ENEC approvals and CE marking, which may be a necessary requirement to meet building codes for the installation of electrical equipment.

The environmental specification of a power supply is a major factor in its selection for lighting applications. Knowing the ambient temperature range where it will be used is one thing, but it is vital to allow for any increase that may result from heat dissipation when operating in an enclosed space. As the earlier review of target applications highlighted, protection against dust, moisture, and the ingress of other contaminants is important to ensure safe and reliable operation. Performance, in this regard, is usually specified with an IP Rating (ingress protection), where the first digit refers to solid objects of decreasing size (down to dust particles). The second digit ranges from vertically falling drops of water through to complete immersion, e.g. IP67 provides total protection against the ingress of dust and the immersion in water for short periods. Other environmental specifications may cover compliance with requirements for electro-magnetic interference (EMI), either protecting the unit from power line surges (due to lightning or the operation of heavy electrical plant) or ensuring it does not generate interference affecting other devices. Industry bodies or government agencies like the FCC usually define such specifications.

Just as important as its environment performance is the reliability and lifetime specification of a power supply. The concern here is that LED technology promises device lifetimes of around 50,000 hours, which equates to over 10 years of typical use. Consequently, designers and installers of LED lighting want to match this performance with similar specifications for the other components used in these systems. Currently power supplies are perceived as the weakest link in the chain, despite the fact that more and more PSU manufacturers are now designing their products to achieve greater than 50,000-hour life (e.g. the CUI VLED15-230-350 PSU referred to above and shown in Figure 3).

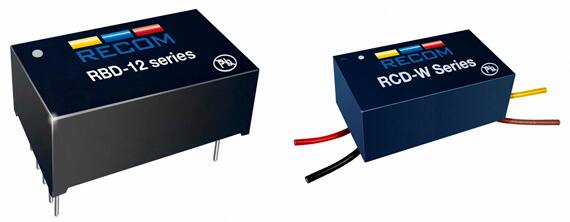

The capability of power supplies to support dimming of LED lights has already been mentioned in the context of certain markets and applications, e.g. domestic lighting, where it may be an essential part of the requirement specification. For other applications, the option to provide dimming may be a prudent choice to provide flexibility in achieving desired lighting levels. Dimming can be achieved in a number of ways and appreciating the different approaches will influence the right choice of lighting power supply. The retrofit market for LED lighting is largely driven by the goal of saving energy. Moreover, despite their higher price, LED lamps do overcome some of the objections people have had previously when replacing incandescent bulbs with compact fluorescent lamps (CFLs), e.g. the slow start/warm-up of CFLs and their reduction in light output with age. CFLs are also not generally compatible with the AC mains type of dimming controls used with incandescent lights. Fortunately, certain supplies, like the CUI VLED15-230-350, address this problem and can use the chopped AC input waveform to regulate its output current and achieve the desired dimming effect. Other PSUs that offer constant current (CC) mode operation, like the Emerson Network Power LDS70-58-U01, provide dimming with switchable output current settings. An alternative method, employed in the –H03 version of the Emerson PSU, and supplies from other manufacturers such as the RBD-12-0.35/W and RCD-24-0.35/W/X1 models from RECOM Power (shown in Figure 4), uses a 0 to 10 V control signal to continuously adjust the output current; this method may sometimes be referred to as resistive dimming, where a potentiometer is used to set the dimming level.

Switchable and analog dimming methods are fine for certain applications, where the light level is either preset or adjusted by a simple control, but varying the LED brightness in this way can also result in color variations. Therefore, where a constant color temperature is required, pulse width modulation (PWM) of the output current will ensure that the LED is always being driven at its rated current, with the brightness dependent on the duty cycle of the PWM waveform. PWM dimming is also more suited to the control of distributed lighting using multiple power supplies. The RECOM Power supplies referred to above both offer PWM dimming control as an alternative to analog control, as do the TDK Lambda ALD214012 and Microsemi LXMG1960-28-01 that we will review shortly.

Understand the merits of various example power supplies

The purpose of this section is not just to draw attention to particular manufacturers’ power supplies as examples of products in their class, but also to see how such products are specified and to pull out some of the differentiating features.

Emerson Network Power’s LDS70-58-U01 (Figure 1) is a compact 70 W rated AC/DC converter that accepts mains input from 100 to 240 VAC and delivers 58 VDC at up to 1.2 A. This unit offers the flexibility of operating as either a constant voltage (CV) or constant current (CC) supply with current adjustment (in CC mode) achieved by DIP switches. Two other options are offered, either with no current adjustment or with a 0-10 V analog control input. Emerson also has versions of its 70 W design with 12 V, 5 A outputs and other ranges that provide various voltage/current combinations with higher and lower power ratings (25 W and 100 W). The LDS70 series is intended for systems that require a life in excess of 50,000 hours. The units feature current limiting, short circuit, overvoltage and overtemperature protection, and will operate with case temperatures from -40°C to +80°C. Ingress protection options are available from IP64 to IP67 but all models meet other environmental specifications for power factor, harmonic, surge immunity and EMC compliance as well as EN, UL, CSA and CE safety requirements. Overall, these PSUs from Emerson address a broad range of medium to high power applications for both indoor and outdoor use.

CUI Inc.’s VLED15-230-350 (Figure 3) is a 17 W AC/DC constant-current supply with a 350 mA output current suitable for driving LED strings with a total forward voltage drop between 24 to 48 VDC. This unit operates from a 176 to 265 VAC (for nominal 230 V mains supplies) input, but there is an equivalent model for 90 to 135 VAC input (nominal 120 V). There are also models with similar power handling capacities that support lower output voltage ranges (with correspondingly higher drive currents). The interesting feature of this design, noted already, is that dimming is possible with standard TRIAC-based incandescent light dimmers that chop the AC supply (or with ELV dimmers that employ reverse phase control). This makes this series of PSUs particularly suited to retrofit applications in the home or office. These CUI units have comprehensive protection, safety, and compliance specifications, with operation from -30°C to +90°C and a long life of >50,000 hours.

RECOM Power also manufactures AC/DC PSUs for LED lighting, but here we will consider DC/DC converters, which are typically used to drive LED strings in an individual light fitting, where a suitable DC supply voltage is already available, either from a battery or distributed from another source. These units offer highly efficient operation with constant current outputs and either digital PWM or analog voltage dimming - PWM control also enables remote ON/OFF. The pinned connection version is suited for mounting on a circuit board while the wired version is IP67 rated. The RBD-12-0.35/W model is a buck-boost LED driver, which allows for step-up or step-down conversion, and is specified for 8-36 VDC input and 2-40 VDC output at 350 mA with a typical 92% efficiency. The RCD-24-0.35/W/X1 is just a buck converter (step-down), again with a 350 mA output rating but with even higher efficiency, typically 96%. These PSUs are very compact (see Figure 4) and operate over -40°C to +85°C and are part of RECOM’s ‘Lightline’ range of DC/DC converters that includes higher current rated models (up to 1200 mA). All are complemented by appropriate environmental, safety and emission specifications similar to the other PSUs reviewed above and clearly de rigueur for products of this type.

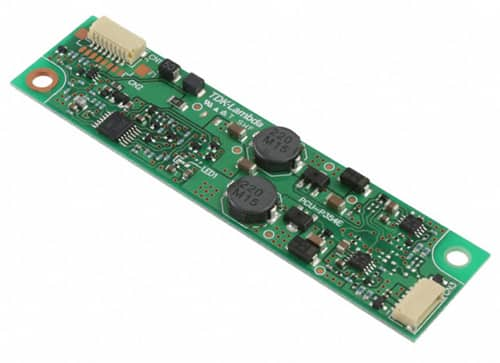

TDK Lambda and Microsemi both offer board level, constant current, DC/DC boost-converter LED driver modules, which at first glance may not appear appropriate for the types of lighting application this article has focused on. This is because they are primarily targeted at backlighting for LCD displays. However, these modules may be just the solution for the design of a custom display case or for backlighting signage, particularly where driving LED strings that may be physically separated. The TDK Lambda ALD214012 is a 6 W unit with two output channels, each rated at 140 mA with either analog or PWM dimming. The Microsemi LXMG1960-28-01 is a 5 W unit configured for six LED strings at 25 mA each, again with analog or PWM dimming. The string current can also be set with DIP switches to values between 10-25 mA.

Summary

LED lighting for broad commercial and domestic use is coming of age. While there is a near-term market for replacing existing incandescent and compact fluorescent lamps, there are also burgeoning opportunities in many other lighting segments, where the advantages of LED technology can be fully exploited in new designs and installations. Key to all these is the ability to provide power to drive the LEDs and get the most out of the performance they offer. Addressing this demand requires an understanding of the various end-markets for LED lighting to appreciate the specifications we need to consider in order to select an appropriate power supply.

This article has attempted to provide this insight by first looking at the applications, then considering some key operating and environmental factors before finally looking at some example power supplies to see how their specifications suit these different requirements.

References:

- Emerson Power Network - LED PSU product training module

- CUI Inc. - LED PSU product training module

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。