8 Things You Didn't Know About Perspex Acrylic Sheets

2025-05-15 | By Kitronik Maker

License: See Original Project

Courtesy of Kitronik

Guide by Kitronik Maker

As Perspex® Acrylic sheets are one of the most popular materials found in Design and Technology departments we thought it would be interesting to share some facts that many people may not know.

We've picked 8 things that we think many people won't know about this highly versatile and widely used design material.

How many did you know?

Perspex® Is A Brand Name:

Many people don’t realise that Perspex is actually a brand name. Perspex is a premium acrylic which guarantees that it is of the highest quality. The Perspex® Acrylic brand is owned by a company called Lucite International, who are the global leader in Acrylics.

Perspex® Acrylic Is Made in the UK:

Perspex sheets are manufactured in Darwen here in the UK. This is one of the reasons we selected them as our acrylic supplier as many of the other brands of acrylic sheet are manufactured outside of the UK.

Perspex® Acrylic Is Older Than You Think:

Perspex® cast acrylic was first manufactured in the UK in 1933, a year later it was trademarked. Since then, it has become a household name and can be seen all around us.

Perspex® Sheets as An Alternative to Glass:

Perspex® Acrylic is very light; it weighs less than half the weight of glass for the same sized sheet and is as transparent as optical glass. It’s also very strong and some types of acrylics have a much greater resistance to impact than glass does and when it does shatter, it does so more safely than glass. Perspex is also a better thermal insulator than glass and much easier to work with and shape.

Perspex® Acrylic Can Be Used to Protect Against Light Damage:

Special UV grade Perspex® sheets can be used to block damaging ultraviolet light, without making them any less see through. They are so effective that you can find them in Art galleries and Museums around the world protecting exhibits and valuable works of art.

Perspex® Acrylic Is Recyclable:

Perspex® Acrylic is fully recyclable and, as such, any off cuts from your Perspex Sheets can be put into your recycle bin. If you have the facilities and the equipment, you can also recycle any off cuts into new items. For some great ideas on recycling check out this What to Do with Scrap Perspex article.

Perspex® Acrylic Can Be Bent into Shape:

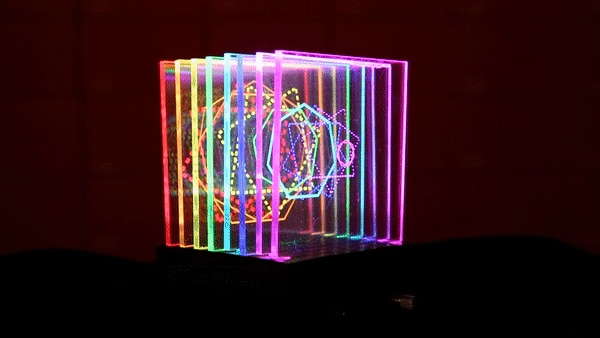

Although Perspex® Acrylic is hard and rigid it can still be bent into shape. Not only can you use heat to make Perspex® Acrylic more malleable and thus make bending possible, you can also use kerf bending. Kerf bending/cutting is when you cut slots in a material that make it possible to bend the material. A laser cutter offers an ideal way of cutting slots in the Perspex® Acrylic. The cases in the above picture were made using kerf bending, you can find more information on these speakers here.

This Photograph is the property of Just Add Sharks. Used with permission.

Perspex® Acrylic Can Be Engraved, Machined and Routed:

Perspex® Acrylic is easy to engrave using either a pantograph, CNC engraving machine or laser cutter. You can also machine and route it provided you follow best practices. Further information on how to work with Perspex® Acrylic can be found on our Working with Materials resource.

©Kitronik Ltd – You may print this page & link to it but must not copy the page or part thereof without Kitronik's prior written consent.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.