Sysmac

Omron 的全集成自动化平台

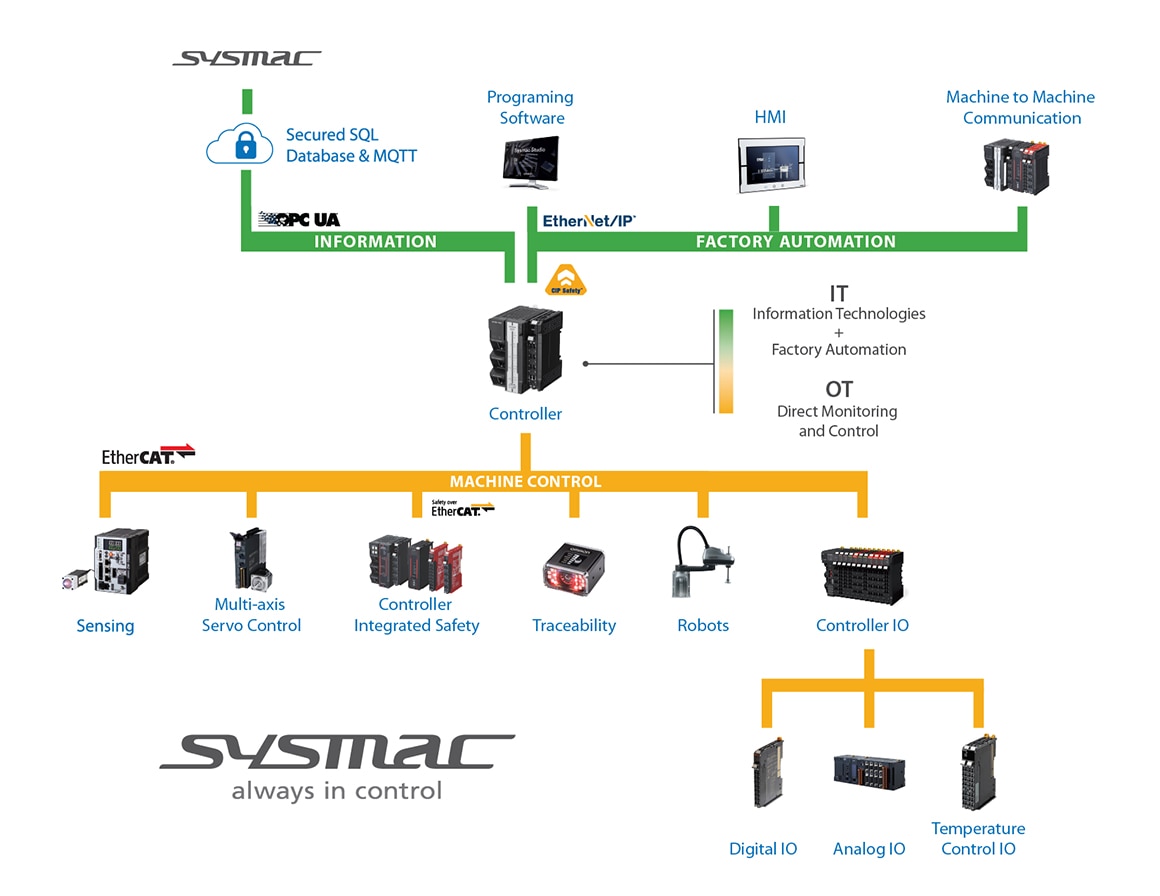

Sysmac 是一个集成自动化平台,致力于对关键制造过程提供完全控制。Sysmac NX 机器控制器系列可同步控制所有机器设备,并提供先进的连接功能。Sysmac Studio 是一个真正集成的程序环境,使用户能够在全球范围内设计、调试和部署程序。Sysmac 利用为实时执行任务而设计的全球开放式协议网络,使整个架构保持连接。

通过一个软件、一个控制器和一个连接,Sysmac 始终处于掌控之中。

- 信息

- 工厂自动化

- 控制器

- 机械控制

Sysmac Studio 是一个独特的环境,它将逻辑、运动和驱动、机器人技术、安全、可视化、传感和信息技术集成到一个项目中,从而降低了学习曲线和操作中的软件成本。团队开发和集成模拟是使 Sysmac Studio 不仅成为开发工作室,而且成为真正生产力工具的关键因素。一个软件就能完成所有事情。

面对日益增长的性能需求,NA 系列人机界面终端可快速、轻松地实现动态直观的用户界面,从而提高生产率并最大限度地减少停机时间。

与 NX 兼容的设备种类繁多,需要各种 I/O 单元。Sysmac NX I/O 产品组合拥有超过 120 个 I/O 单元,可随时连接到车间的任何设备,让您始终掌控一切。其超高速内部总线系统与 EtherCAT 网络的分布式时钟同步。由此产生的全系统确定性 I/O 操作使机器制造商能够提高机器生产率和产出质量。

控制器是 Sysmac 平台的枢纽,也是集成自动化解决方案的核心。与所有 NX 系列运动速度和精度一样,一个集成控制器可满足对逻辑顺序和数据传输的极端要求,而不会影响软件扩展成本。NX 系列机器控制器减少了硬件,因为控制器共享相同的 I/O 连接,并且所有控制器都可以在 Sysmac Studio 软件上进行编程。

Sysmac NX502 控制器

希望降低成本、缩短编程和实施时间,最大限度地降低网络攻击风险的公司将在新型 NX502 中找到强大的解决方案。该控制器旨在集中和简化生产线控制。NX502 通过多达 254 个 CIP 安全连接、多达 62 个运动轴、256 个 EtherCAT® 节点、80 MB 程序内存、1 Gbps EtherNet/IP 端口,以及标配 OPC UA 和 SQL 来实现这一目标。

NX502 机器控制器降低了硬件和软件扩展成本,因为所有 NX 系列控制器共享相同的 I/O 连接,并且都可以在 Sysmac Studio 软件上进行编程。由于安全程序可以在单个 Sysmac Studio 环境中得到验证,因此也减少了编程时间。此外,由于 CIP Safety 允许 NX502 在已使用 CIP Safety 兼容机器人的情况下使用,因此还可将实施时间降到最低。

NX502 的 CPU 单元左侧最多可容纳 4 个 EIP 卡,通过增加可在同一 CPU 上运行的机器总数,降低了设备总的生产线控制成本。这是因为每个 EIP 卡都会创建一个子网,将机器级网络与数据库网络和工厂级网络分开。每张卡都进一步扩展了 NX502 CPU 的 EIP 和 CIP 安全连接。

面对日益增长的性能需求,NA 系列人机界面终端可快速、轻松地实现动态直观的用户界面,从而提高生产率并最大限度地减少停机时间。

多轴伺服控制

精确控制和协调机械和机器人中多个轴的运动,实现复杂和同步的运动,从而提高性能和多功能性。

Omron NX 系列集成安全控制器可与标准 NX I/O 自由组合。

Omron NX 系列集成安全控制器可与标准 NX I/O 自由组合。

自动化任务,执行复杂操作,并协助各个行业的人类,提高效率、精度和生产力。

与 NX 兼容的设备种类繁多,需要各种 I/O 单元。Sysmac NX I/O 产品组合拥有超过 120 个 I/O 单元,可随时连接到车间的任何设备,让您始终掌控一切。其超高速内部总线系统与 EtherCAT 网络的分布式时钟同步。由此产生的全系统确定性 I/O 操作使机器制造商能够提高机器生产率和产出质量。