Harvested RF Powers Remote Sensors

投稿人:DigiKey

2011-12-14

Capturing energy

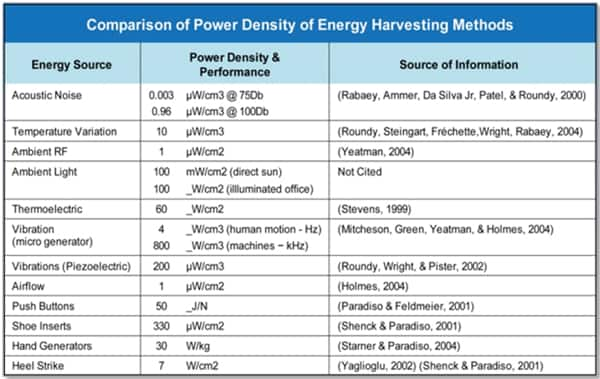

Recently, there have been numerous advancements in the field of Energy Harvesting. Many everyday sources of energy, such as light, wind, temperature, vibration, radio waves, and even PH have been cleverly converted to usable energy using a variety of techniques (see Figure 1). The challenge is how to convert the tiny amount of energy generated by these technologies to a form that can perform a useful function, such as powering an environmental sensor in a reliable fashion.

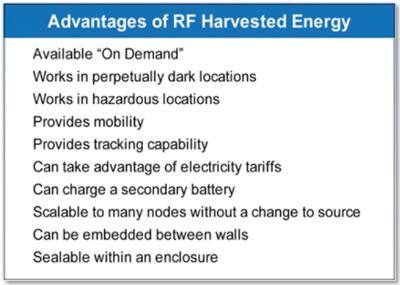

The key is in the selection of the harvested source and the components, and a careful analysis of the power budget. The advantage of RF energy as a power source over the other harvesting technologies is that it can be obtained from ambient energy, or controlled by the use of a dedicated transmitter. Devices using RF harvesting can be untethered and work in almost any environment.

RF as a power source

RF energy can be harvested from sources such as broadcast TV and radio stations, mobile phones and base stations, and transmitters in unlicensed bands including 915 MHz, 868 MHz, or 2.4 GHz, making RF harvesting commercially viable worldwide. RF enjoys many advantages over other energy sources. It does not depend on the time of day, does not require exposure to heat or wind, and can be moved freely within the range of the transmission source. It can be completely controlled, meaning that the energy can be transmitted continuously, on a scheduled basis or on demand. A rechargeable battery or super capacitor can be utilized to store the converted RF energy for operation during the peak periods.

For example, Powercast’s RF energy-harvesting receivers convert the received RF signal into DC, regulate the output power, and directly power or charge a secondary energy store. These receivers can also recover low-rate data that is broadcasted along with the power signal.

Low-power component selection

A convenient and reliable power source is just part of the solution. The other part is proper system design to maximize performance with the tiny amount of energy that is provided. There are two ways to contend with this limitation. The first is the use of extremely low power components, and the second, the implementation of power balancing.

Fortunately, a general drive toward lower-power electronic components is occurring. This is fueled by consumer demand for portable products, and has ushered in a new wave of low power microcontrollers, analog, radios, and communication protocols that are a perfect complement to RF harvesting.

Microcontrollers have evolved to extremely low power consumption levels. For example, Microchip’s PIC24F with eXtreme Low Power (XLP) technology consumes only 20 nA while sleeping, and can execute code with currents as low as 8 µA.

To complete an environmental sensor, analog components and a radio are needed. The radio tends to be the power-budget buster. This is driven by two factors, the protocol used and the Transmit/Receive (Tx/Rx) current. New radios have started to address the Tx/Rx current issue, and now feature receive currents as low as 3 mA. This certainly helps to reduce power consumption, but often it is the wireless communications protocol that is the driving factor.

Power balancing

When working with the tiny amounts of power generated by energy harvesting, long execution times and bloated wireless protocols will consume the power budget. The key to reigning in the execution time of protocols is to select a protocol that allows for scaling functionality according to need. Eliminating unnecessary overhead and handshaking will significantly lower power consumption. Several companies now offer proprietary protocols that allow for minimalist implementation, such as Microchip’s MiWi™ protocol. With these protocols, radio transmission times have been driven as low as 5 ms, dramatically reducing power consumption.

Further improvements can be made through the use of two power-management techniques: charge-based execution and state-of-charge monitoring.

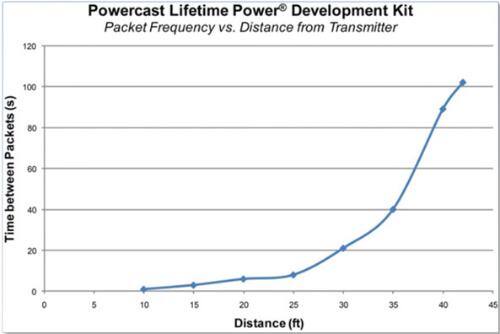

For charge-based execution, power is cut off completely from the sensor system. Only when the RF harvester has collected enough energy is the sensor enabled. The main benefit of this technique is that the device consumes zero power while replenishing the energy reservoir. The frequency of the sensor’s execution is dependent upon the rate of charge to the reservoir, which is impacted by the distance to the RF source, the receiving antenna, and obstructions such as walls. This works well when the sensor is located such that the frequency of sensor operation is fitted to the needs of the overall system. The RF harvester can also use the received signal strength (RSSI) as a mechanism for controlling the rate of data transmissions to avoid flooding the network with unnecessary packets. Figure 2 shows an example of a charge-based system.

If the RF harvester is charging a battery, a microcontroller can be used to monitor the length of the charging cycle and estimate the state of charge. With an estimate of the available charge, the microcontroller can calculate the runtime based on what sensor operations are performed. This is accomplished by recording the current consumed during the various parts of the sensor operation. For example, the sensor node might consume 100 µA when measuring the sensor’s output, and then consume 20 mA during the radio transmission of that data. The microcontroller can use this information to estimate the charge that will be depleted each time one of these functions is completed. By comparing the charging and depleting, the state of charge is known.

This method has the advantage of being able to taper off the frequency of sensor transmissions, based upon state of charge. The system can even call for help, by transmitting a message to the RF power source to send more power.

Practical energy harvesting pays off

With proven technology now available in the marketplace providing a platform for prototyping new products, RF harvesting is a viable option for a wide range of applications. Careful selection of components and power balancing allow this technology to replace battery-powered sensors en masse. The advantages of RF harvesting, such as control of the source and the ability to operate in any environment, not only make RF harvesting very practical, but may also drive RF harvesting to the mainstream.

Whether due to environmental regulation, social-responsibility policy or just plain economics, energy harvesting is gaining traction. To avoid the unpredictable whims of the sun, the wind and the temperature, there is only one proven and reliable option, RF harvesting.

Note: PIC is a registered trademark of Microchip Technology Inc. in the USA and other countries. MiWi is a trademark of Microchip Technology Inc. All other trademarks mentioned herein are the property of their respective companies.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国