System Wiring and Interconnect for Rooftop Solar Panels

投稿人:电子产品

2011-11-16

Even a single solar panel tied into a building’s electrical supplies requires some specialized wiring components specific to photovoltaic technology. Typical rooftop applications require stringing multiple panels together and connecting them to system electronics and, ultimately, the main power system.

Any fixed PV installation contains a few key components. There will be at least one solar panel, and DC-to-AC conversion electronics are necessary to feed the harvested energy into standard household wiring or the electrical grid. Obviously, the system also needs to be interconnected, and various wiring products exist to help make the connection from the panel to the electrical load.

For residential or industrial rooftop solar systems, careful attention needs to be paid to the regulatory requirements. In the U.S., the minimum baseline for this is the National Electrical Code (NEC), but many other state and local regulations may apply and must be consulted prior to any system design or installation. Once minimum applicable regulations for the location have been established, system components can be specified

The second consideration will be the long-term reliability of the wiring system, considering that the components will be outdoors and subjected to potentially harsh conditions. The need for weatherproofing needs to be taken into account as well. As an example, the NEC demands that PV wiring insulation must have 90°C, sunlight, and wet service resistance. This includes the connector ends of each wire.

Making the connection

Labor costs for installing PV systems are a significant and quite possibly the largest portion of the overall system cost for many configurations. Therefore, hardware and wiring that can save time will limit the labor cost during initial installation as well as for any future maintenance events.

For many PV panels, the first connection is likely determined by the manufacturer. Many suppliers produce panels with a junction box already assembled. Although convenient, this will pre-determine the wiring connector system that must be used to connect the panels. Amphenol Helios H4, Molex SolarSpec, and TE Connectivity SOLARLOK are three popular options.

In some circumstances, one may work with bare panels requiring the use of a panel junction box. In addition to providing a weatherproof housing for connecting the to the solar cell bus inside the panel and providing a means to connect to the rest of the wiring for the installation, the panel junction box should incorporate both fuses for safety and diodes for ensuring current flow is strictly out of the panel.

The SOLARLOK A99646-ND panel mount junction box can be used on solar panels with up to four contact rail foils. Three SL1010 protection diodes are included. External connection is by direct wire which offers flexibility in the choice of downstream wiring components. Attaching the junction box (as seen in Figure 1) to the solar panel can be simplified with the use of 3M VHB tape adhesives such as the ½-in. 3M6468-ND.

Beyond the junction box of each panel, the wiring has to at least deliver the harvested energy to the load. Often, the system is more complex, with several individual panels strung together. Interconnecting multiple panels is an essential part and a major consideration for all but the smallest of rooftop solar installations. For series interconnection of panels, there are connectors keyed and labeled by polarity. For 10-AWG wire the male and female positive side couplers (as seen in Figure 2) are part numbers are A98825-ND and A98829-ND respectively. A98826-ND and A99561-ND are used on the negative polarity side.

Grounding is a very important aspect of any electrical system and no more so than in a photovoltaic system since it is outdoors and exposed to weather and lightning. Simplifying the ground connections avoids any possibility of overlooking them and also reduces the labor cost of the installation. The SOLARLOK A97546-ND grounding clip (as seen in Figure 3) is a simple and effective solution. Solid uninsulated ground wire from 10 to 12 AWG is secured by clamping the plastic housing down by hand. The ground wire is contacted and terminated in one short, single step without requiring any tool. The wire can be released during maintenance by simply prying the clip back to its original open position using a screwdriver.

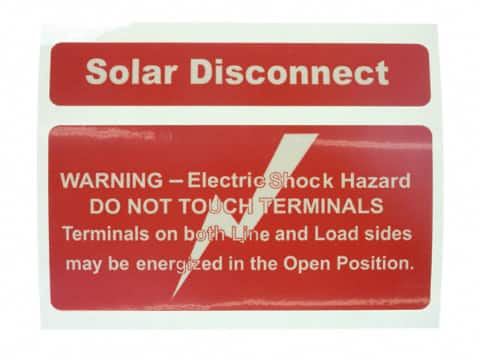

Although connectors are keyed to ensure accurate interconnection of panels and electronics, the electrical code also demands specific labeling of various locations. Since dangerous voltages can exist, the NEC demands that disconnect points be labeled to ensure that appropriate precautions are exercised when any future repairs are undertaken. SD1000-ND Solar Disconnect labels (as seen in Figure 4) are printed with UV-resistant ink and employ adhesives designed to withstand harsh environmental exposure. An overcoat is also applied to provide additional UV protection.

Approved wires are also available that meet or exceed NEC and EU standards. TE Connectivity has solar cable in three gauges – 10, 12, and 14. Wire construction is dual wall insulation with polyolefin jacket. Quantities are available to fit various sizes of solar installations with 100, 500, or 1,000 feet available in the 10-AWG size. A97543-100-ND is the 100-ft. quantity of the largest 10-AWG cable that is UL listed at 600 V. Much larger 2,500-ft. rolls are available for smaller 14-AWG wire.

The SOLARLOK connectors employ metal contact end pins that are attached to solar cable by crimping. These components work best with the tools designed for use with the connectors. The A98836-ND is the SOLARLOK crimping tool for the connectors in the 10 to 12-AWG wire sizes.

When multiple strings of panels are used, these can be interconnected and protected through the use of a combiner box. The SOLARLOK A103886-ND combiner box accommodates up to five strings of panels. The solar cable input side consists of 10 pre-terminated SOLARLOK connectors. The combiner box is used to convert the SOLARLOK wiring and connections to standard household electrical wire at the output. This box has four knockouts with standard lock tabs, mounting slots, and a prewired grounding clip on the output side.

The SOLARLOK combiner box offers a hinged cover with internal transparent front lid for added safety. Inside, there are five prewired fuse blocks and a terminal block for grounding.

Rooftop solar installations have attracted a great deal of interest in recent years. Although much of the attention is paid to the underlying solar cell technology in terms of efficiency and cost per watt, the wiring and interconnection components are not only essential but a major design consideration for any permanent solar installation.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国