Smart Grid Builds on Smart Meters, Lighting, Sensors

投稿人:DigiKey 欧洲编辑

2015-10-13

The "smart grid" is the next major step in the transformation of the AC power grid. The existing grid provides power from centralized power plants, and has little or no insight into individual user (industrial, commercial, or residential) loads and use; at the same time, users have little grasp of their own use and load-based costs. Further, the existing grid architecture is not well suited for very local, independent sources (home-based solar panels, for example), which provide power back to the grid at unpredictable times, as well as drawing from the grid.

The smart grid is intended to provide power and balance loads more efficiently. It also provides better insight to end users into costs versus time-of-use for load leveling; equally important, it will accommodate the increasing number of intermittent local sources which may feed power back to the grid when conditions warrant doing so, or store power for later use.

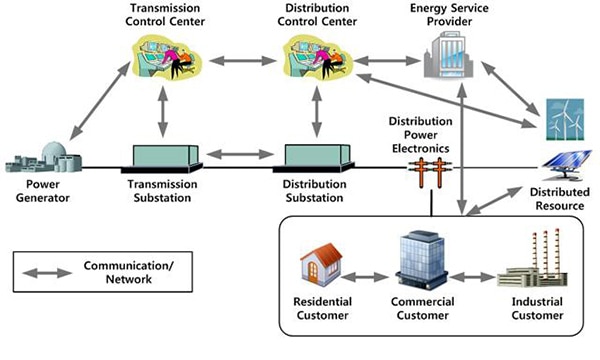

One key to making the smart grid into reality is the introduction of sensors at all levels of the hierarchy of the grid (Figure 1). According to a report from market research firm IHS, the market for smart-grid related sensors will grow nearly ten-fold from 2014 to 2021, reaching $350 million. Working with these sensors, the smart grid relies on smart power meters installed at each user site, to inform both users and the power companies of power availability, loading, and operating costs. These meters will be linked to smart control of internal appliances and lighting, and local power sources/storage, as well as the power company grid.

Figure 1: The smart grid is a major step-up from the traditional power system and grid; it is designed not only to increase source, transmission, and use efficiency, but also allow for small-scale sourcing and localized storage.

Smart grid overview

Historically, the AC-power grid linked multiple generating stations, whether fueled by coal, oil, gas, water, or nuclear fuel, into a mesh so that any of these sources could support users anywhere in the system. The utilities which operated the power plants and the grid could measure how much power and energy were passing through each part of the grid, adjust availability and throttle if needed, and could measure the cost of energy consumed by each end user (kW-Hr) via various telemetry techniques.

However, that was the limit of the insight they had. The time constant of their feedback loop was relatively large, as it responded primarily to large-scale variations such as use of less power during the night and ramp-up/down periods in the morning and evening, with a somewhat steady-state high value during the day. Of course, in our increasingly 24/7 world, even these traditional patterns are changing.

The objective of the smart grid is to allow for a flexible combination of energy sluices, distribution paths, and storage, all driven by the need to balance available options and dynamically adjust the mix as needed, in a fairly fast, real-time environment. A goal of a successful smart-grid implementation is to minimize the need for large-scale power plants or additional large-scale transmission lines. To make this happen, strong financial incentives are being used to encourage load-leveling, power use during slack periods, local power sourcing, and even local storage (for example, see Tesla Motors' recent announcement of their Powerwall system for homes and offices).

High-level architecture supported by lower-level building blocks

Predictions about the potential flexibility of the smart grid and the benefits it may yield are enticing, but reality is that to make it happen will take many low-level building blocks at the end-user level. This is especially the case for residential installations, where every home is just a little different, and there is no "building management" professional staff. The smart grid functional pyramid begins with monitoring and perhaps utility-based control of the energy being delivered to, or supplied by, the home. There are several stages to making this happen.

First, each home will need a smart meter, known as Advanced Metering Infrastructure (AMI) to measure power use, and provide data to the utility for billing and tracking. It also offers insight to the consumer for monitoring usage and pricing, and possibility of more hands-on control of energy use. AMI, in turn, works with a home monitoring/control function called Residential Energy Management (REM) which uses a utility-installed Home Area Network (HAN) to talk to the meter, thermostat, lights, and other devices which are to be monitored and perhaps controlled; the HAN connectivity is via a wireless link or power line communications (PLC).

In general, consumers are suspicious about the idea of utility control of energy use amount and time, and the inroads it will make are unclear. An alternative, the utility-provided REM is replaced by one provided by the consumer called an independent REM (iREM), which connects via the AMI metering subsystem and actively monitors energy use, yet allows the users to maintain personal control.

ICs, sensors, software are key elements

Translating these broad, high-level goals into reality, such as the smart meter and smarter appliance/fixture control, is where the high-volume opportunities are for vendors, but with severe cost pressure.

Market research firm IHS believes that global shipments of smart meters will triple between 2011 and 2016 to about 62 million units, and this will result in a doubling of the associated semiconductor market during the same period. In the report summary, Jacobo Carrasco Heres, industrial electronics research analyst for IHS noted that, "The original motivation for replacing conventional meters with smart meters was energy savings. However, a more compelling incentive is the instrumentation of the grid. With the use of smart meters, utilities finally will have a well-mapped grid that will enable them to plan electrical generation and manage their resources more efficiently.” A few examples illustrate the steps that vendors have taken to make these critical building blocks of the smart grid into practical developments.

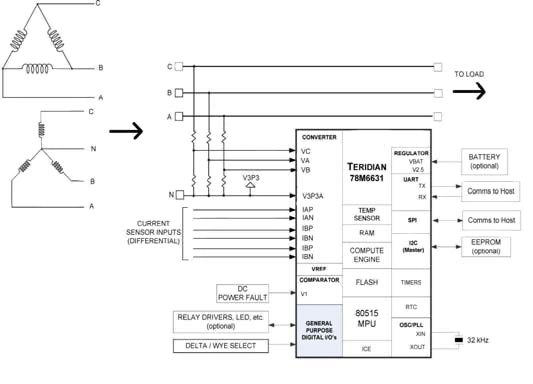

A leading smart-meter IC is the Maxim Teridian™ 78M6631, a highly integrated, 3-phase power-measurement and monitoring system-on-chip (SoC) (Figure 2). This device contains a 22-bit delta-sigma A/D converter, an 8051-compatible MPU core, and a 32-bit compute engine (CE) for processing the AC- line data. The 78M6631 is designed for power and quality measurements in applications requiring both delta and wye 3-phase configurations.

Figure 2: The Maxim Teridian 78M6631 power-measurement and monitoring SoC not only implements the bulk of the smart-meter function, but also accommodates a variety of line transducer types and 3-phase connection configurations.

The device provides six analog inputs to the A/D converter (three differential current and three voltage) for interfacing to current and voltage sensors used for AC-line pickup. The device provides better than 0.5% accuracy over a wide 2000:1 dynamic range. For interfacing to a host processor, the 56-Pin TQFN-packaged IC includes SPI, I2C, and UART I/O. It also includes basic digital I/O ports for controlling LEDs that tell the user the smart-meter status, for driving external relays, and even for allowing selection between input transducers.

A smart-meter IC by itself, regardless of functionality or level of integration, is only part of the story. Maxim offers application software which can be loaded into the 128 kB flash memory as firmware to provide analysis and system adjustments, including:

- True RMS current and voltage calculations

- Active, reactive, apparent, fundamental, and harmonic power calculations

- Fundamental and harmonic current and voltage calculations

- Line-frequency and power-factor calculations

- Phase compensation (up to ±18° at 60 Hz)

- Built-in calibration routines

- Programmable alarm thresholds

This combination of suitable line current/voltage transducers, the Teridian IC, embedded firmware, and analysis will meet the various worldwide performance and regulatory standards for accuracy, timeliness, and data reporting.

Residential and commercial (office) lighting is an area where the smart grid can be integrated to save significant power. Unlike HVAC, which must run to maintain the desired temperature (although doing so efficiently is a goal), lighting has more flexibility. Users can elect to adjust the lighting level to meet their needs depending on available outside light, room occupancy, and other factors. Lighting is also a source of waste heat, which can be a good or bad thing depending on the outside temperature.

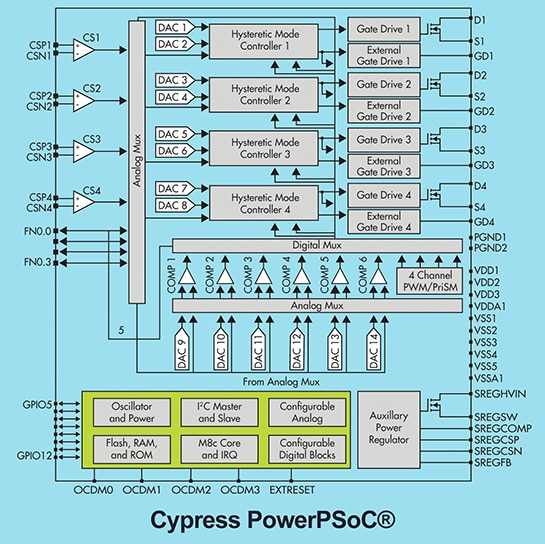

As many installations are switching over to LED-based lamps for efficiency, longevity, and dimmability (with the appropriate control circuit and algorithm), vendors are offering LED-optimized smart-lighting ICs. One example is the CY8CLED0xD/G0y family of PowerPSoC® Intelligent LED Drivers from Cypress Semiconductor Corp., comprising over a dozen related ICs which differ in amount of memory, I/O count, and some internal functions (Figure 3). Each device consists of five main blocks: PSoC core, digital system, analog system, system resources, and power peripherals (which include power FETs, hysteretic controllers, current -amplifiers and PrISM/PWM modulators). These PowerPSoC family devices are designed to replace traditional MCUs, system ICs, and the numerous discrete components that surround them.

Figure 3: The diverse CY8CLED0xD/G0y family of PowerPSoC ICs from Cypress Semiconductor is designed specifically for smart driving of LED lighting, which is the fast-growing alternative to the venerable incandescent bulb and CFL bulbs, but which has unique and carefully monitored drive characteristics.

Each PowerPSoC features an array of integrated power peripherals as well as digital-control functions. The power peripherals include:

- Up to four independently operated MOSFETs (32 V/1 A) which can drive high-power LEDs

- Up to four programmable hysteretic controllers to provide controlled current output for the LEDs

- Up to four programmable low-side gate drivers to support voltages above 32 V, for use with external MOSFETs

- Floating-load buck, floating-load buck-boost, and boost-converter topologies for flexibility in meeting the different voltage requirements of various applications

- Switching frequency up to 2 MHz, which allows using smaller, less expensive inductors

- An auxiliary power regulator to power the device from a single power supply

- 16-bit dimming for lighting applications that require high-resolution dimming

On the digital-control side, users have access to:

- Eight programmable-digital blocks for functions such as timers, counters, PWMs, and UARTs

- Six programmable analog blocks for functions such as amplifiers, ADCs, DACs, filters and comparators

- At least 16 kb of flash memory

- An 8-bit microcontroller

Within the PSoC devices, the configurable power, analog, digital, and interconnect circuitry enables a high level of integration to support industrial, commercial, and consumer LED-lighting requirements.

Simple sensors can also make a big difference. At a lowest functional level of smart-grid and smart-energy interaction, the use of a room-occupancy detector can eliminate wasted lighting energy, especially as some areas only see highly intermittent, fragmented use for short periods (think restrooms). That's where a basic component such as the Zilog Zmotion ZRE200BP PIR (passive infrared) detector offers large benefits for modest investment.

Conclusion

The smart grid offers great potential for energy saving and efficiency from generation to use and even to storage. Translating the grand concept into a reality requires a substantial upgrade in facilities and equipment at all stages of the grid system, with much work being done at local and residential sites where costs must be kept low, ease of installation and use is vital, and tangible benefits must be realistic. Vendors of components such as power-metering ICs, lighting- and energy-control ICs, and even basic sensors are playing a large role in this upgrade to a grid that is more self aware, flexible, and resilient.

References

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。