将产品设计转向可持续的净零排放

投稿人:DigiKey 北美编辑

2024-04-24

各种主要力量正在形成合力,以确保企业在未来几十年内对可持续发展的重大需求。在全球范围内,各国政府、企业和民众正团结起来,支持 2050 年实现净碳零排放目标。我们建议产品设计师在未来的产品计划中考虑净零可持续性因素,否则就有可能把业务拱手让给更能应对激烈市场压力的竞争对手。

全美制造商协会 (NAM) 在 2022 年底发布报告称,58% 的受访制造商高管认为,可持续性对未来竞争力至关重要。这一比例远高于 2019 年的类似调查。[i] 就制造商和生产商而言,可持续性是指在不损耗能源、材料和水等资源的情况下,长期延续流程和工作实践的能力。

2015 年,在联合国主持下,196 个国家通过了《巴黎协定》这一具有法律约束力的国际条约,将净零排放这一术语编纂成法。[ii] 随后在 2017 年,联合国政府间小组将 2050 年定为实现二氧化碳 (CO2) 净零排放和大幅减少非 CO2 排放的目标。尽管缺乏普遍的执行命令,但净零排放目标正被越来越多的政府和企业所采纳:

- 包括美国在内的 30 个国家已承诺到 2050 年实现政府运营净零排放目标,并且到 2030 年减排 65%。

- 在全球 2000 家上市公司中,已有一半的公司设定了净零排放目标,占全球前 2000 强公司年收入的 66%。[iii]

- 在接受 NAM 调查的人中,45% 的人表示他们的公司已经制定了正式的净零目标,30% 的人计划到 2030 年实现这一目标。[iv]

零净排放的商业影响

净零排放的可持续性对商业的影响是巨大的。

美国国防机构在 2022 年的产品支出估计为 2100 亿美元,而民用机构的支出为 490 亿美元。[v] 欧盟委员会在提出净零排放技术产品制造生态系统时预计,到 2030 年,全球大规模制造的净零排放技术市场每年将达到 6000 亿欧元。[vi]

制造商将生产电动汽车和基础设施、现代化电网、建筑控制器和热泵等所需的产品。此外,在碳捕捉技术方面的投资将推动对新产品设计和现有工厂改造的解决方案的需求。

向净零排放的转型需要对资本进行大规模重新分配,到 2050 年,资本总额可能达到数万亿美元或等值规模。这将要求制造业的运营发生巨大转变,从如何为工厂和工具提供动力,到采用更轻、更强的材料。

整个制造供应链都将受到影响。制造商在衡量其净零排放进展时,必须计算其总体碳足迹,包括其供应商的净零排放进展。希望从非零排放商机中获利的公司需要证明它们正在努力实现净零排放目标。

企业必须计算从材料采购到报废管理的整个产品生命周期内的碳影响。设计师必须学习新技能,调整或替换现有流程,并对运营改革,使可持续发展成为设计的核心理念。主要的最佳实践领域包括:

- 采用可减少材料用量并回收废品的循环经济法,以制造新材料和新产品。

- 优化流程,实现产品开发低碳化,包括在产品生产过程中尽量减少材料消耗和资源使用。

- 进行新型设计理念创新,投资新的工具和技术,以实现更节能的产品和流程。

- 通过关注变革管理问题,包括提拔组织机构中可持续发展的倡导者、消除工人的恐惧和抵触情绪,以及重新掌握和引进实现净零排放目标所需的新技能,从而养成净零排放意识。

- 利用数字化服务扩展机械系统,从而根据需要提供新的特性和功能。

利用供应商的进步推动发展

Analog Devices, Inc. (ADI) 是一家市值 120 亿美元(2023 财年)的全球半导体领导企业,它将模拟、数字和软件技术结合在一起,在现实世界和数字世界之间架起了一座桥梁。该公司的产品有助于推动数字化工厂、建筑自动化、移动和数字医疗领域的进步。该公司承诺到 2050 年或在更早的时间内实现净零排放,到 2030 年将范围 1 和范围 2 的碳排放量减少 50%,到 2030 年将 ADI 生产设施中的废物实现 100% 转移。

ADI 的目标是,通过高能效运动控制、精确的低功耗资产健康监测以及自适应智能检测、执行和控制,来降低能耗、延长资产使用寿命并减少原材料用量。

ADI 拥有丰富的产品组合,可为产品设计师提供各种元器件,以提高工业自动化和智能建筑应用的能效:

变速驱动器:据估计,电动机的用电量约占工业用电量的 65%。[vii] 从历史上看,这些电动机大多是固定旋转设备,如果全部配备变速驱动装置,全球能源使用量可减少可达 10%。[viii] ADI 变速驱动解决方案集成了高性能电流和电压检测、稳健的隔离、高密度电源管理和无缝连接等功能。

AD8410A 和 AD8411A 等高电压、高带宽电流检测放大器可在分流电阻器上进行双向电流测量,从而提供可提高驱动性能的反馈,并确定电机的带宽和响应时间,从而确保电机以最高效率运行。较小机箱内的电源管理是一个重要的设计考虑因素。ADI 提供 MAX17692 等反激式开关稳压器集成电路,该器件可在次级侧整流器导通期间直接从初级侧反激式波形感应出隔离输出电压。由于无需次级侧误差放大器和光耦合器,与传统反激式转换器相比,可让设计人员节省多达 20% 的印刷电路板 (PCB) 空间 [ix]。

位置编码器:具有精确位置和扭矩控制功能的高效伺服驱动电机可加快复杂部件的加工速度,从而优化能源使用。ADI 的精密信号调节和转换技术可在嘈杂的工业环境中精确地测量小幅度信号。ADI 提供的产品有助于开发高性能位置编码器解决方案,这些解决方案具有先进的控制回路性能、高效率和高度集成的电源管理技术,可降低加工过程中所需能耗,提高工厂生产能力。

ADI 技术有助于加快高性能位置编码器解决方案的上市时间。该公司为光学、磁性、旋转变压器和线性可变差分变压器等传感器提供编码器信号链解决方案。ADP320 三路输出低压差 (LDO) 具有低静态电流、低压差电压和宽输入电压范围等特点,可为光学和磁编码器信号链中的所有元器件供电。

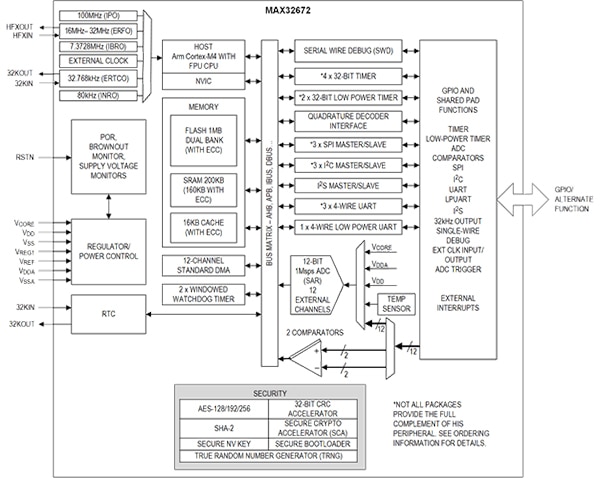

ADI MAX32672 的简化框图如图 1 所示。这是一款超小型、超低功耗、高集成度和高可靠性的 32 位微控制器,它能够在不影响电池寿命的情况下进行复杂的传感器处理设计,并为传统设计中的 8 位或 16 位微控制器提供了一条简便的、低成本的最佳途径。

图 1:MAX32672 微控制器的简化框图。(图片来源:Analog Devices, Inc.)

图 1:MAX32672 微控制器的简化框图。(图片来源:Analog Devices, Inc.)

编码器的尺寸越来越小,这有助于设计人员在电机上安装编码器,以支持先进的制造能力。

集成电源管理:ADI 提供在紧凑 IC 中实现了高集成度微功率管理解决方案,具体包括 LT3029 等低噪声稳压器(适用于通用线性稳压器、电池供电系统和微处理器内核/逻辑电源等应用),以及 LT3024(适用于手机、无线调制解调器和频率合成器)。

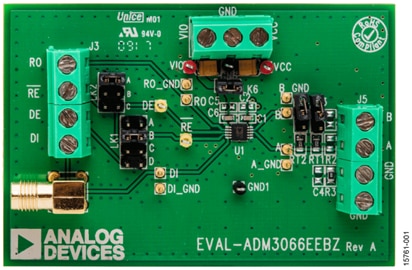

可靠的连接:ADI 提供半双工和全双工 RS-485 收发器,可在高数据速率下进行可靠的数据传输。例如,ADM3066E 和 ADM3067E 可在多点总线传输线上实现 50 Mbps 的高速双向数据通信,并具有允许在总线上使用多达 128 个收发器的 1/4 单位负载输入阻抗。设计人员可以借助一些评估板(如 EVAL-ADM3066EEBZ(图 2))来评估和演示这些收发器的功能。

图 2:ADI 的 EVAL-ADM3066EEBZ 评估板可容纳采用 10 引线 MSOP 封装的 ADM3066EBRMZ 半双工 RS-485 收发器。(图片来源:Analog Devices, Inc.)

图 2:ADI 的 EVAL-ADM3066EEBZ 评估板可容纳采用 10 引线 MSOP 封装的 ADM3066EBRMZ 半双工 RS-485 收发器。(图片来源:Analog Devices, Inc.)

建筑控制器:要使新建建筑和现有建筑更具可持续性,就需要使用测量、连接和处理技术来控制暖通空调和照明、感知占用情况并监测环境条件。这将推动对智能边缘设备的需求,从而实现数字化建筑系统。

建筑自动化系统通常包含多个控制器和不同节点,其中每个节点都需要可靠的连接。ADIN1110 是一款低功耗单端口收发器,集成了媒体访问控制 (MAC) 接口,要求更低的系统级总体功耗,并集成了电压供应监控和上电复位电路,以提高系统级稳健性。

智能建筑需要对边缘电源进行有效管理。ADI 的 LTC4296-1 可为 10Base-T1L 控制器和交换机提供单对以太网供电 (SPoE) 电源,通过一根双绞线以太网电缆传输高达 52 W 的功率和数据。LTC9111 是一款符合 IEEE 802.3cg 标准的 SPoE 电源设备控制器,特别适用于建筑和工厂自动化中基于分类的系统。

结束语

到 2050 年实现净零排放可持续发展的需求在不断增长,这为支持制造业创新、再加工和推进新技术的产品带来为了巨大的机遇。虽然 2050 年看似遥远,但本文引用的数据强调,源于政府、企业和社会的压力已经促使许多公司将 2050 年净零碳排放和 2030 年碳中和目标纳入当前战略。每个供应商最终都可能需要展示在实现这些目标方面取得的进展。如果产品设计人员能积极主动地将这些目标融入到他们的规划、流程和零部件供应中,那么他们就能从有史以来最大规模的工业变革中获益。

资源

- https://nam.org/sustainability-is-a-top-manufacturer-priority-survey-shows-19992/?stream=business-operations

- https://unfccc.int/process-and-meetings/the-paris-agreement

- https://zerotracker.net/analysis/new-analysis-half-of-worlds-largest-companies-are-committed-to-net-zero

- https://nam.org/sustainability-is-a-top-manufacturer-priority-survey-shows-19992/?stream=business-operations

- https://gaoinnovations.gov/Federal_Government_Contracting/

- https://ec.europa.eu/commission/presscorner/detail/en/IP_23_1665

- https://iea.blob.core.windows.net/assets/98909c1b-aabc-4797-9926-35307b418cdb/WEO2019-free.pdf

- https://new.abb.com/news/detail/75020/abb-urges-greater-adoption-of-high-efficiency-motors-and-drives-to-combat-climate-change-global-electricity-consumption-to-be-reduced-by-10

- https://www.analog.com/media/en/technical-documentation/data-sheets/max17692a-max17692b.pdf

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。