Low-Profile Coin Cells for Low-Power Wireless Designs

投稿人:电子产品

2013-03-07

A benefit of higher frequency RF is that components get smaller. Smaller components mean less material, so components can be less expensive as well. With smaller, lower-cost electronics, more gadgets take advantage of the new wireless possibilities that open up. Take Bluetooth® headsets as a case in point. Imagine trying this with a CB antenna strapped to your head. It is not feasible at CB bands, but very doable at 2.4 GHz.

When designs get very small, the battery can be the largest component – and obstacle – in your assembly. Microelectronic processors, sensors, buttons, and touch zones keep getting smaller, but the energy density physics we have available do not seem capable of shrinking appreciably without reducing capacity.

Energy harvesting shows some promise, as does solid-state and supercapacitor-based energy storage systems. To date, however, batteries are the most widely deployed energy storage devices with proven reliability and track records. Coupled with power management systems and algorithms, designers are doing more with less power than ever before.

New battery technologies, features, and sizes are keeping pace with the increased demand for higher energy density, as well as small size. This article looks at small, low-power wireless designs and the low-profile coin cells and holder assemblies engineers have at their disposal. All parts, datasheets, tutorials, and development kits mentioned are available online at DigiKey’s website.

Getting the best fit

If your product is a throwaway or a one-time-medical-use type of device, you can possibly get by without a coin cell holder. However, unless you are willing to fabricate your own mechanical coin cell assembly, you will want to use one of the many available form factors and configurations, available off the shelf for both replaceable and rechargeable types of coin cells. As expected, holders are designed for specific cells and should be used for those cells only.

What may not be so easy is fitting the correct cell and battery for the correct application. It is more than just voltage and amp/hour capacity. Batteries have different chemistries and characteristics, such as internal resistances, and can do a fine job when discharging at a steady rate, but may have trouble when surge demands are put on it.

Unlike most applications that may draw a startup current surge and then settle down into a relatively steady-state current draw, wireless applications often use power in a burst-like fashion. A lot depends on the wireless modulation and protocols.

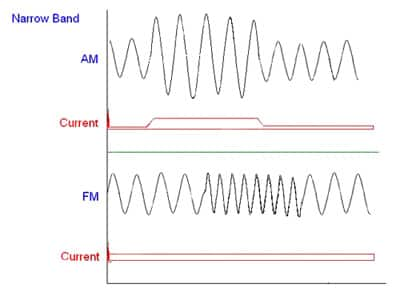

For example, a simple narrow-band FM or FSK type of modulation will use a relatively steady amount of power (Figure 1). Once keyed and transmitting, the current draw is relatively steady. AM types of modulation are consistent, as well. Carrier On – Carrier Off types of systems may suffer a little transmit ripple bleeding onto the current flow, but proper amount of capacitance can help rectify this.

Figure 1: Narrow-band wireless links may use a small surge upon power up or keying the transmitter. After that, power usage is relatively consistent.

Modern wireless devices fall into two overall categories: streaming and connect/exchange based. Streaming links, once connected, continuously transmit data at some predetermined rate. Wireless sensors, headsets, and wearable medical devices fall into this category. The average current consumption for streaming applications resembles the narrow-band AM/FM/FSK types of curves and is relatively consistent.

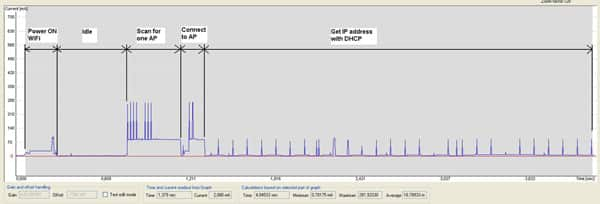

Connect/exchange-based systems can have wireless sections idling quietly in the background, then wake up with a roar of current. Then, different modes of signaling and data transfer can affect power usage going forward. Take, for example, a low-power Wi-Fi based module design using a low-power microcontroller and Wi-Fi chipset (Figure 2).

Figure 2: The current draw for Connect/Exchange based systems such as Wi-Fi imposes the need for a battery system to supply high current spikes for short durations. This reduces estimated battery life when compared to steady discharge rates.

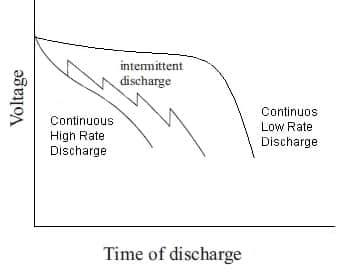

While idling quietly, it is consuming 4 mA on average. As it scans and connects, it can peak out at around 300 mA for short durations. Even while waiting for an IP address, it peaks at over 100 mA for pulsed durations. You can play some tricks, such as using static IPs to reduce time and energy, but your battery system with its internal resistances must be able to handle this type of discharge. In addition, the discharge curve for a pulsed application more resembles a saw tooth than it does a smooth curve (Figure 3).

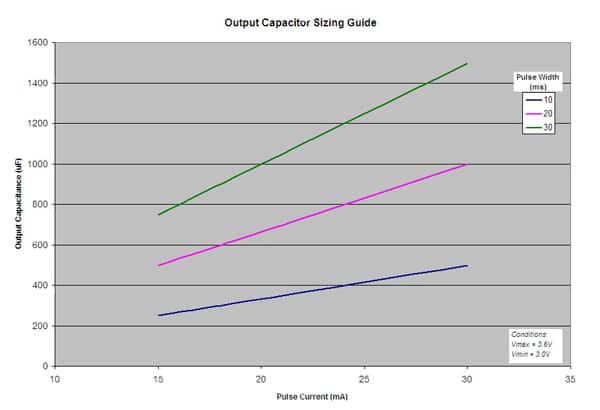

Another way to help solve this is to use external capacitance to provide charge when needed. Typically, capacitors have very low internal resistances so they can pulse-burst without heating up inside the storage cell, which degrades life expectancy (Figure 4).

Available choices

Lithium is the highest energy-density available battery to date, and is very attractive for size- and weight-constrained designs. They come in throwaway and rechargeable flavors, and are available in larger canister, high capacity forms as well as the coin cell configuration, which has become a very popular way to go. The diameters can vary quite a bit from 4.8 mm to 30 mm and so can height, capacity, and voltages.

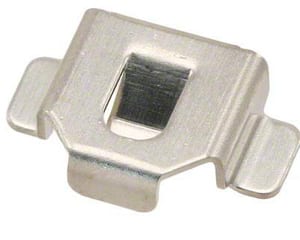

The smallest profile can be attained if you use the PC board as a contact point. In this case, the use of a retaining clip can provide a reliable solution. Very-low-profile and small-sized designs may be able to use the MPD 0.1 in.-high, 414 battery series and retainer clips such as the MPD BK-414-TR. The 4.8 mm-diameter cell comes in rechargeable lithium in 2 and 3 V, at around 1 mAh capacity (Figure 5). These may be useful for short-range wireless sensors that spend most of their time asleep.

Because of high volume use, several battery types are cost effective and commonly available, such as the 3 V lithium 2032 style. While the larger 20 mm diameter can be daunting, the 0.17 in. above-board height lets this battery fit into thin designs. Additionally, its typical capacities of around 210 mA hours make this battery usable for many processor-based electronic devices. MPD offers the BK-912-TR retainer clip for this style.

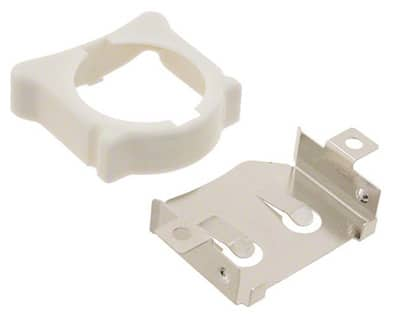

The TE Connectivity 120591-1 is an example of an entire assembly that insulates the bottom of the housing from the battery contact. The 0.25 in. height above the board is higher than the retaining-clip-only approach, but may offer easier battery replacement.

A topless, clip detent holder from Keystone is the 1060TR, which lowers this to 0.217 inches high with top mount access, as well. Keystone also makes the 301 holder for the 3032 style coin cells that have even more capacity.

The lithium, 3 V, 3032 cell features an impressive 500 mA-hour rating while still retaining a low-profile height, in this case 0.235 in. using the Keystone holder. MPD also makes the BH3000 for these 30 mm-diameter, high-capacity cells.

When a little extra height can be tolerated, stacking cells in a single housing can increase the energy density. An example based on retaining clips is the MPD BHX2-2032-SM, which stacks two CR2032-style cells on top of each other (Figure 6). The 3 V cells in series yield 6 V, which is more directly usable for 5 V systems and can eliminate some power conditioning on the boards. The removable top hat makes battery replacement easier as well as keeping assembly height to only 0.295 in. You can find an MPD training module covering battery holders for wireless applications on the DigiKey website.

Keystone also offers the 1027 stackable battery connectors for CR2032 battery styles. At 0.352 in. high, it amortizes the retainer’s height over the two batteries, providing even higher energy density.

Conclusion

While battery-powered designs may have wireless benefits and features in common, their battery technology and energy needs can differ greatly. Different applications may impose tough constraints environmentally (from the extreme cold of the remote Arctic to the high temperatures of an autoclave sterilization cycle in medical devices). Even wireless standards place different requirements on system batteries.

Ultimately, you will prioritize your own needs and determine the battery chemistry and technology to use. We have provided a variety of small, low-profile coin cells and battery holders for you to consider. For more information on these products, use the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。