Improving Energy Efficiency in Wearables Using Low-ESR Capacitors

投稿人:DigiKey 欧洲编辑

2016-05-04

The wearable device has become an important application area for electronics. Wearables provide users with the ability to measure their health and fitness and make it easier to keep in touch online without having to keep picking up and inspecting a smartphone. But wearable design brings challenges to the electronics system designer.

The primary design objective for most wearables is to ensure that energy consumption is kept to a minimum. Users dislike having to frequently recharge wearable devices, especially if they need to be plugged into a power source. Wireless charging offers greater flexibility and better user acceptance but can lead to longer charging times because of the limits on the rate at which energy that can be transferred to the device.

Optimizing the energy consumption of a wireless device demands attention at every level of the design, including that of the power-delivering subsystem itself. In almost all cases a wearable will employ a switched-mode DC/DC converter to provide a regulated, constant voltage to the electronics when fed from a battery cell that will typically provide a falling voltage as the stored charge dissipates.

Many DC/DC converters employ a combination of inductor and capacitor on the load side to smooth out voltage and current peaks. This is especially important for the energy-saving pulse-skipping modes that many converters for portable and wearable devices support. The pulse-skipping mode is generally used during periods of low-activity as an alternative to the pulsewidth modulation (PWM) voltage regulation that is used when the load is fully active.

Load transients tend to lead to voltage spikes that are exacerbated by the equivalent series inductance (ESL) and impedance in the output capacitors at high frequencies. Recovery from the load-step transient also leads to voltage overshoot and undershoot depending on the direction of the load transient. Reducing the impact of the supply-voltage error uses energy stored in the output capacitor as well as the response time of the converter. For reliable voltage regulation, it is important to have a wide loop bandwidth within the DC/DC converter, low equivalent series resistance (ESR) in the output capacitors and sufficient output capacitance for adequate storage.

The ability to maintain an efficient and low-noise output under load changes depends first on how much overshoot and undershoot the regulator will suffer and, second, how much ripple voltage occurs at the switching frequency.

Peak overshoot, as well as undershoot, is approximately the load-step current multiplied by the impedance of the output capacitors at the loop crossover frequency. Similarly, the ripple voltage is approximately equal to the output capacitor’s impedance multiplied by the peak-to-peak inductor current.

The peak-to-peak inductor current can be reduced by increasing the size of the inductor, but this is likely to lead to problems in PCB and enclosure design. It is hard to make high-value inductors that have the thin shape often required for wearables. As a result, it makes sense to focus on reducing the impedance of the output capacitors at the key switching frequencies. This impedance, although it will exhibit a frequency dependent minimum at the self-resonant frequency, is largely controlled by ESR.

Figure 1: How impedance changes with increasing frequency.

Although an ideal capacitor stores all of its energy in the dielectric, any real-world capacitor will exhibit some series resistance. The ESR is generally due to losses in the dielectric as well as in the electrode and termination materials. At low frequencies up to the kilohertz region, the main contributor to ESR is dielectric loss. At higher frequencies, the ESR caused by the metals in the electrodes and terminations begin to dominate. These losses become significant because of skin effect and tend to increase with the square root of frequency.

ESR is typically expressed in milliohms at specific frequencies by most manufacturers and the measurements are performed at various frequencies – so it is important to consider how well the capacitor performs in terms of ESR close to the switching and loop-crossover frequencies in a power supply. Because of the frequency dependence, the ESR performance of capacitors is important also in RF circuits. RF capability is an important characteristic of today's wearables. Although the relatively low power levels associated with protocols such as Bluetooth Smart and IEEE 802.15.4 limit the amount of transmit power that can be lost, the ESR of capacitors in the RF section can account for a significant component of the overall losses.

Multilayer ceramic capacitors (MLCCs) tend to have low ESR and ESL, but they have traditionally been limited on capacitor size. Traditionally, electrolytic and tantalum capacitors offer larger capacitance values but tend to have higher ESR ratings. Recent advances in the design of polymer capacitors that were developed to improve on the reliability of tantalum devices have delivered significant reductions in ESR. The polymer dielectric used in these newer technologies also overcomes the problem of tantalum ignition that can make it more difficult to achieve the desired safety performance and rating for the product.

Figure 2: The construction of a low-ESR polymer capacitor

The POSCAP family of polymer-electrolyte capacitors made by Panasonic offers ESR down to just 6 mΩ, with the minimum impedance generally being encountered between 100 kHz and 2 MHz – which tends to suit the switching frequency range of many high-efficiency DC/DC converters.

The POSCAP capacitors use a highly conductive polymer electrolyte to improve ESR compared to aluminum electrolytic and tantalum capacitors. There are different subfamilies of POSCAP to support tradeoffs in terms of frequency-dependent behavior. The TPSF series, for example, has a low-ESL characteristic that suits applications where low impedance at high frequency is important. They demonstrate minimum impedance close to 1 MHz. Compared to ceramic capacitors, the capacitance of the POSCAP devices are more stable over changes in temperature and show very little bias under voltage.

A further advantage of the use of a polymer-based capacitor is that it does not suffer from piezoelectric effects. A number of MLCC technologies use dielectrics that have piezoelectric properties, causing them to expand and contract under changes in charge. If the DC/DC converter has a switching frequency that operates in the audio range, this oscillation in shape can cause unwanted audible noise.

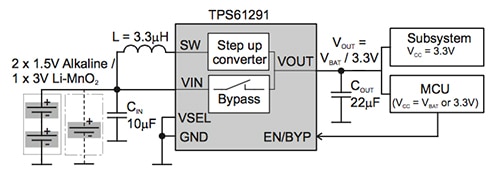

However, MLCCs are widely available and, thanks to the introduction of high-frequency DC/DC converters that need comparatively small output capacitors, can be used in the output stage of power supplies for wearables. For example, the TPS 61291 made by Texas Instruments is designed to be usable with relatively small capacitors, demanding just a 22 µF load capacitor for a typical 3.3 V supply delivering up to 100 mA of current. The DC/DC converter suits low-power devices such as wearables thanks to a low-power, 15 nA quiescent mode.

Figure 3: Circuit diagram showing use of a 22 µF capacitor with the TI TPS 61291.

DC/DC converters like the TPS 61291 will work with MLCCs that exhibit an X5R or X7R temperature profile, such as those made by AVX. The family includes X5R devices with up to 100 µF capacitance. Other types of capacitor dielectric, such as Z5U may not be suitable for power-supply filtering because of their change in behavior with temperature.

The combination of switching power supplies and wireless low-power communications can lead to issues with EMI. The converters can generate high-frequency EMI: the high-switching speed causes voltage ringing. To suppress noise and protect the semiconductor components, an RC snubber circuit is often connected in parallel to the input stage of the power supply. Because the MLCCs normally used in these circuits are optimized for low ESR, with EMI suppression they often require an additional resistor to maintain sufficiently high impedance levels in order to complete an effective resonant circuit. This can lead to an unwanted reduction in the efficiency of the power supply, sometimes by as much as 4 percent, which is problematic for devices that need long battery life.

An alternative is to use a noise absorber capacitor such as the YNA made by TDK. The YNA type device is designed with an intentionally higher ESR, so is able to suppress excess ringing without the use of an additional resistor when used, typically, in the input stage of a DC/DC converter.

Generally, the ESR due to the conductor resistance of MLCCs falls with the number of layers in the internal electrode, which leads to ESR falling with increasing capacitance. The architecture of the YNA allows the ESR to be raised above its normal value by combining different internal electrode patterns.

Although wearables bring with them an increased focus on low-power design techniques, incorporating low- and controlled-ESR capacitors into the circuitry around DC/DC converters can help maximize energy efficiency and boost battery lifetime.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。