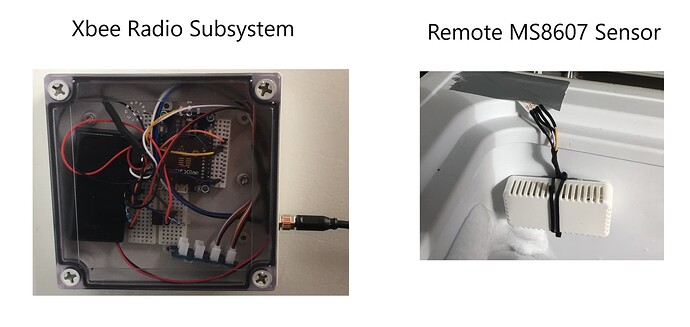

本项目使用 Digi Xbee3 无线 Zigbee 模块和 TE Connectivity MS8607 传感器来实现电池供电的 Zigbee 环境传感器。Xbee3 上的 ADC 用于测量系统电池电压。传感器数据和电池电压被发送到 Machinechat 的 JEDI One IoT 平台并进行监控。

项目描述

该项目的用例是监控冷冻机的温度和传感器系统的电池电压。MS8607 能够测量气压、温度和湿度,但本项目专注于温度和电压参数。MS8607 通过电缆连接到 Xbee 无线电,因此可以放置在冷冻机内以测量温度(还测量湿度以进一步了解冷冻机性能)。监控电池电压以确定电池何时退化到需要更换的程度。

Xbee3 模块上运行的 MicroPython 应用程序用于连接到 Zigbee 网络并读取传感器和 ADC。传感器数据和电池电压被发送到 Zigbee 协调器,然后通过 Machinechat 的 Zigbee 到 WiFi 传感器桥转发到 JEDI One IoT 平台(详见项目)。JEDI One 在具有以太网/WiFi 网络连接的 Raspberry Pi 4 上运行。

硬件

- RASPBERRY PI 4B/4GB

Raspberry PI 4 Model B 带 4GB SDRAM(用于运行 Machinechat JEDI One) - XB3-24Z8PT-J

Digi Xbee3 Zigbee PCB 天线 THT 模块 - DPP901G000

TE Connectivity MS8607 压力/温度/湿度传感器分线板 - TPS2042P

Texas Instruments TPS2042P 电源分配开关

软件

- JEDI One

JEDI One 是一个即用型 IoT 数据管理软件解决方案。功能包括:从传感器、设备和机器收集数据;构建直观的实时和历史数据及系统视图仪表板;创建规则以自动监控和响应数据条件;通过电子邮件和短信接收警报通知。 - MicroPython

MicroPython 是 Python 3 编程语言的精简高效实现,包含 Python 标准库的一小部分,并优化为在微控制器和受限环境中运行。

实施

传感器电路由两节 AA 碱性电池供电。主要组件包括 Digi Xbee 3 Zigbee 模块、Texas Instruments TPS2042 电源分配 IC 和 TE Connectivity MS8607 传感器板。TPS2042 用于控制 MS8607 和电池分压电路的电源。MicroPython 应用程序代码实现了 60 秒的睡眠周期,在读取和传输传感器数据之间以最小化电流消耗并延长电池寿命。下面的示意图展示了电路的实现方式。

Digi Xbee3 MicroPython MS8607 传感器项目详情

在MicroPython项目中,Xbee3模块被配置为Zigbee终端设备,其网络ID与Zigbee到WiFi桥接中使用的Xbee3协调器相同。MicroPython应用程序加入Zigbee网络,并启动一个无限循环,该循环启用TPS2042P开关,读取MS8607传感器,读取电池电压,禁用TPS2042P开关,构建传感器数据消息,发送到Zigbee协调器,休眠60秒并重复。

1 - 在Xbee3上设置MicroPython并刷入应用程序固件。参考Digi MicroPython编程指南

2 - 代码详解(PyCharm项目:sensor_ms8607THV,文件名:main.py)

初始设置并连接到Zigbee网络

# project: sensor_ms8607THV

# description: Xbee3 Zigbee Micropython MS8607 sensor project that sleeps x seconds, then wakes to send temperature,

# humidity, and battery voltage readings to coordinator

# Default template for Digi Xbee3 projects

import utime

import ustruct

import machine

import time

import xbee

from machine import Pin

x = xbee.XBee()

# list of commands in hex for MS8607 pressure sensor

c_reset = 0x1E # reset command

r_c1 = 0xA2 # read PROM C1 command

r_c2 = 0xA4 # read PROM C2 command

r_c3 = 0xA6 # read PROM C3 command

r_c4 = 0xA8 # read PROM C4 command

r_c5 = 0xAA # read PROM C5 command

r_c6 = 0xAC # read PROM C6 command

r_adc = 0x00 # read ADC command

r_d1 = 0x44 # convert D1 (OSR=1024)

r_d2 = 0x54 # convert D2 (OSR=1024)

p_address = 0x76 # pressure sensor i2c address

# list of commands in hex for MS8607 humidity sensor

h_address = 0x40 # humidty sensor i2c address

r_user = 0xE7 # read user register command

w_user = 0xE6 # write user register command

t_temp = 0xE3 # trigger temperature measurement, hold master

t_humi = 0xE5 # trigger humidity measurement, hold master

# set register format

REGISTER_FORMAT = '>h' # ">" big endian, "h" 2 bytes

REGISTER_SHIFT = 4 # rightshift 4 for 12 bit resolution

# set i2c clock to 100KHz

i2c = machine.I2C(1, freq=100000)

#Zigbee coordinator adddress in house

TARGET_64BIT_ADDR = b'\x00\x13\xA2\x00\x41\xAA\xCB\xBA'

# slave_addr = 0x76

# reset pressure sensor

def reset_ps():

slave_addr = p_address

data = bytearray([c_reset])

i2c.writeto(slave_addr, data)

return data

# scan i2c bus for active addresses

def scan_I2C():

devices = i2c.scan()

return devices

def read_c1(): # read PROM value C1

data = bytearray([r_c1])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to integer

return value

def read_c2(): # read PROM value C2

data = bytearray([r_c2])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to unsigned integer

return value

def read_c3(): # read PROM value C3

data = bytearray([r_c3])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to unsigned integer

return value

def read_c4(): # read PROM value C4

data = bytearray([r_c4])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to unsigned integer

return value

def read_c5(): # read PROM value C5

data = bytearray([r_c5])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to unsigned integer

return value

def read_c6(): # read PROM value C6

data = bytearray([r_c6])

i2c.writeto(slave_addr, data)

raw_c = i2c.readfrom(slave_addr, 2) # raw C is 2 bytes

value = int.from_bytes(raw_c, "big") # use builtin to convert to unsigned integer

return value

# start D1 conversion - pressure (24 bit unsigned)

def start_d1():

# print ('start D1 ')

data = bytearray([r_d1])

i2c.writeto(slave_addr, data)

# start D2 conversion - temperature (24 bit unsigned)

def start_d2():

# print ('start D2 ')

data = bytearray([r_d2])

i2c.writeto(slave_addr, data)

# read pressure sensor ADC

def read_adc(): # read ADC 24 bits unsigned

data = bytearray([r_adc])

i2c.writeto(slave_addr, data)

adc = i2c.readfrom(slave_addr, 3) # ADC is 3 bytes

value = int.from_bytes(adc, "big") # use builtin to convert to integer

return value

# read humidity sensor user register command 0xE7, default value = 0x02

# default resolution RH 12bit, T 14bit

def read_user():

data = bytearray([r_user])

i2c.writeto(slave_addr, data)

value = i2c.readfrom(slave_addr, 1)

return value

# read rh: send trigger rh command 0xE5

def read_rh():

data = bytearray([t_humi])

i2c.writeto(slave_addr, data)

raw_rh = i2c.readfrom(slave_addr, 2) # raw RH is 2 bytes

raw_value = int.from_bytes(raw_rh, "big") # use builtin to convert to integer

# rh_tc = (-0.15)*(25 - read_temp())# RH temp compensation

rh_value = (((raw_value / 65536) * 125) - 6) # calculate RH

return rh_value

# **************** Main Program *********************************

# set up variables d2, d3, d4 as pin outputs and set to 0

# use D4 to /EN TPS2042D power distribution switch, power MS8607 and voltage divider for ADC pin D0

d2 = Pin.board.D2

d2.mode(Pin.OUT)

d2.value(0)

d3 = Pin.board.D3

d3.mode(Pin.OUT)

d3.value(0)

d4 = Pin.board.D4

d4.mode(Pin.OUT)

d4.value(0) # set low to enable TPS2042P to enable i2c during startup

# set DIO9 and DIO10 to outputs with value 0

d9 = Pin.board.D9

d9.mode(Pin.OUT)

d9.value(0)

d10 = Pin.board.D10

d10.mode(Pin.OUT)

d10.value(0)

# set up ADC with 2.5V reference for pin D0 as analog input

#x = xbee.Xbee()

xbee.atcmd('AV', 1)

apin = machine.ADC('D0')

# delay for 30 seconds (long delay to connect to device if needed after reset)

#print("start 90 seconds delay")

utime.sleep(90)

#print("end 90 seconds delay")

try:

print('i2c scan addresses found: ', scan_I2C())

except:

print('i2c scan addresses not found')

try:

print('perform reset on pressure sensor, code = ', reset_ps())

except:

print('cannot reset pressure sensor')

# read and print humidity sensor user register

# slave_addr = h_address # set humidity sensor i2c address

# print('user register: ', read_user())

# read press sensor calibration PROM

slave_addr = p_address

try:

C1 = read_c1()

C2 = read_c2()

C3 = read_c3()

C4 = read_c4()

C5 = read_c5()

C6 = read_c6()

except:

print('cannot read pressure sensor calibration')

#print('PROM C1 = ', C1)

#print('PROM C2 = ', C2)

#print('PROM C3 = ', C3)

#print('PROM C4 = ', C4)

#print('PROM C5 = ', C5)

#print('PROM C6 = ', C6)

# check zigbee connection

while xbee.atcmd("AI") != 0:

print("#Trying to Connect...")

utime.sleep(1)

print("#Online...")

主循环

# Main loop

while True:

# set pin d4 low to enable TPS2042

# d2.value(1)

d4.value(0)

# delay for 2 seconds to stabilize

utime.sleep(2)

# take ADC reading on pin D0 (voltage divider across supply/battery)

raw_val = apin.read()

val_mv = int((raw_val * 2500)/4095 * 2)

print('supply voltage %d mV' % val_mv)

# start on D1 conversion for pressure sensor

try:

slave_addr = p_address # set i2c address to pressure sensor

start_d1() # start D1 conversion

utime.sleep(1) # short delay during conversion

raw_d1 = read_adc()

#print("D1= ", raw_d1)

except:

print("D1 conversion failed")

# start D2 conversion for temperature

try:

start_d2() # start D2 conversion

utime.sleep(1)

raw_d2 = read_adc()

#print("D2= ", raw_d2)

except:

print("D2 conversion failed")

# calulate pressure and temperature

try:

# difference between actual and ref P temp

dT = raw_d2 - (C5 * 256)

#print("dT= ", dT)

#

Temp = 2000 + (dT * (C6 / 8388608))

if Temp < 2000: # add 2nd order correction when temp < 20C

T2 = 3 * dT ** 2 / 8589934592

OFF2 = (61 * (Temp - 2000) ** 2) / 16

SENS2 = (29 * (Temp - 2000) ** 2) / 16

else:

T2 = 5 * dT ** 2 / 274877906944

OFF2 = 0

SENS2 = 0

if Temp < -1500: # add 2nd order correction when temp < -15C

OFF2 = OFF2 + (17 * (Temp + 1500) ** 2)

SENS2 = SENS2 + (9 * (Temp + 1500) ** 2)

# calculate corrected temp

Temp = (2000 - T2 + (dT * (C6 / 8388608))) / 100

fTemp = int(Temp * 9 / 5 + 32)

OFF = (C2 * 131072) + (C4 * dT / 64) - OFF2 # offset at actual P temperature

#print("OFF= ", OFF)

SENS = (C1 * 65536) + (C3 * dT / 128) - SENS2 # pressure offset at actual temperature

#print("SENS= ", SENS)

Pres = (raw_d1 * SENS / 2097152 - OFF) / 3276800 # barometric pressure

#print('P Temp = ', '%.1fC' % Temp)

#print('P Temp = ', '%.1fF' % fTemp)

#print('T2 = ', T2)

#print('OFF2 = ', OFF2)

#print('SENS2 = ', SENS2)

#print('Pressure = ', '%.1f ' % Pres)

utime.sleep(1)

except:

print("Temp and Pressure calculation failed")

# start on humidity sensor

try:

slave_addr = h_address

RH = int(read_rh() - 3.6 - (0.18 * Temp))

print('relative humidity: ', '%.1f percent' % RH) # temp compensated humidity

except:

print("humidity sensor conversion failed")

# turn off TPS2042

d4.value(1)

# build PTH sensor data payload for battery voltage, temp and humidity

try:

time_snapshot = str(utime.ticks_cpu())

# print_PTH = "PTH_sensor:" + time_snapshot + ":Press:" + str(Pres) + "mB:Temp:" + str(fTemp) + "F:Temp1:" + str(ftemp9) + "F:Humidity:" + str(RH) + "%:#"

# print_PTH = "PTH_sensor:" + time_snapshot + ":Press:" + str(Pres) + "mB:Temp:" + str(fTemp) + "F:Humidity:" + str(RH) + "%:#" #remove MCP9808

print_PTH = "PTH_sensor:" + time_snapshot + ":V_Ba:" + str(val_mv) + ":T_F:" + str(fTemp) + ":H_%:" + str(

RH) + ":#"

print(print_PTH)

except:

print("sensor payload build failed")

Pres = 99

fTemp = 99

RH = 99

# transmit PTH data over Zigbee to coordinator

d3.value(1)

try:

xbee.transmit(TARGET_64BIT_ADDR, print_PTH)

# xbee.transmit(ROUTER_64BIT_x1B2D, print_PTH)

#

except:

print("xbee coordinator transmit failed")

# set pin d4 high to turn off TPS2042P

#d4.value(1)

# print("set d4 high and delay for 1 seconds")

# utime.sleep(1)

# d2.value(0)

# d3.value(0)

print("sleeping for 60 seconds")

#sleep_ms = x.sleep_now(10000, True)

sleep_ms = x.sleep_now(60000, True)

print("woke up ")

该项目的最新源代码:sensor_ms8607THV在github上的链接如下:

设置 JEDI One

1 - 如果Raspberry Pi上尚未安装machinechat JEDI One,请参见以下内容:

- 获取Raspberry Pi版本的JEDI One DK-JEDIONE-RP

- 在Pi上安装,参见Raspberry Pi - 将JEDI One安装为服务

2 - 如果尚未实现,请设置Machinechat与Zigbee到WiFi传感器桥接(详见项目详情)。

3 - 设置JEDI One仪表板

在JEDI One中,选择“Dashboards”选项卡,然后选择“+”以添加新图表并进行配置。

命名图表,选择“Chart Type”,选择“Source”(PTH_xxx),选择“Property”(data2),输入“Units”并输入“Refresh Interval”。重复第二个图表,命名图表,选择“Source”(PTH_xxx),选择“Property”(data1),输入“Units”并输入“Refresh Interval”。完成后,仪表板应类似于下图。

结论

Digi的Xbee3 Zigbee模块、TE Connectivity的MS8607传感器、TI的TPS2042P电源IC和Machinechat的JEDI One物联网平台的结合,形成了一个功能强大的无线监控系统,用于监控冷冻室的温度和无线传感器的电池状态。该项目可以轻松修改以监控其他参数和传感器。JEDI One 可以轻松配置为在条件低于预设限制时提供电子邮件或短信警报。